Home>Finance>What Is Supply Chain And Operations Management?

Finance

What Is Supply Chain And Operations Management?

Modified: December 29, 2023

Learn how finance plays a crucial role in supply chain and operations management, driving efficiency, cost savings, and strategic decision-making. Discover the key principles and practices in this dynamic field.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for LiveWell, at no extra cost. Learn more)

Table of Contents

- Introduction

- Definition of Supply Chain and Operations Management

- Key Components of Supply Chain and Operations Management

- Importance of Supply Chain and Operations Management

- Role of Supply Chain and Operations Managers

- Challenges in Supply Chain and Operations Management

- Strategies for Effective Supply Chain and Operations Management

- Technologies Impacting Supply Chain and Operations Management

- Future Trends in Supply Chain and Operations Management

- Conclusion

Introduction

Supply chain and operations management plays a vital role in the success of any business. It involves the coordination and management of all activities involved in the production and delivery of products and services to customers. From sourcing raw materials to manufacturing, warehousing, and distribution, supply chain and operations management ensures optimal efficiency and effectiveness throughout the entire process.

In today’s highly competitive business environment, companies are constantly seeking ways to improve their supply chain and operations management to gain a competitive edge. By streamlining processes, reducing costs, and increasing customer satisfaction, businesses can enhance their profitability and sustainability.

This article will provide an in-depth understanding of supply chain and operations management, including its definition, key components, importance, role of managers, challenges, strategies, technologies, and future trends. Whether you are a business owner, a manager, or simply interested in the field, this article will offer valuable insights into the world of supply chain and operations management.

Now, let’s dive into the details of this fascinating subject and explore the intricacies of supply chain and operations management.

Definition of Supply Chain and Operations Management

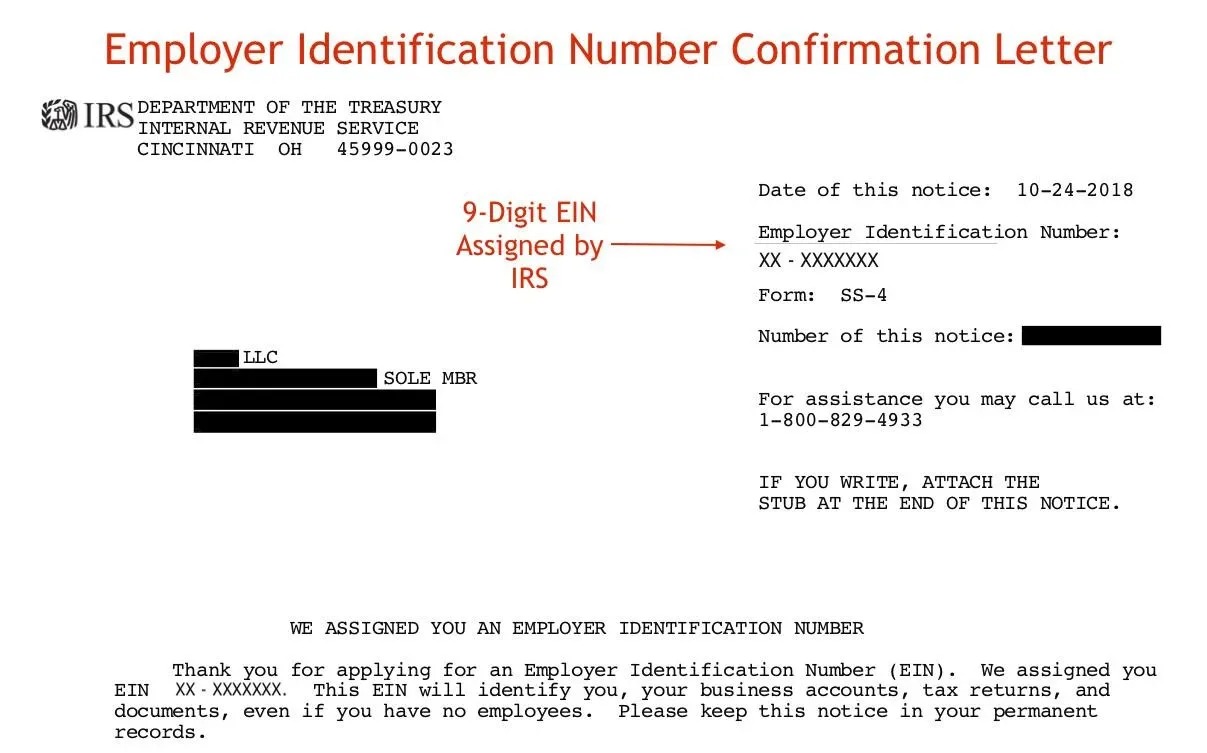

Supply chain management (SCM) is the coordination and integration of all activities involved in the sourcing, procurement, conversion, and logistics management processes. It encompasses the flow of goods, services, information, and finances from the initial stages of sourcing raw materials to the final delivery of the finished product to the end consumer.

Operations management, on the other hand, focuses on the efficient conversion of inputs into outputs. It involves the planning, organizing, and controlling of processes to ensure the smooth production and delivery of goods and services. Operations management encompasses various activities such as production planning, inventory management, quality control, and process optimization.

When combined, supply chain management and operations management form the discipline of supply chain and operations management. It involves the integration and coordination of these two interrelated functions to optimize the overall performance and success of an organization.

At its core, supply chain and operations management aims to enhance customer value and satisfaction by effectively managing the entire value chain. This involves understanding customer needs, aligning supply chain processes with those needs, and delivering products and services in a timely and efficient manner.

Supply chain and operations management also focuses on minimizing costs, reducing lead times, improving quality, and managing risks within the supply chain. It involves collaboration with suppliers, partners, and internal stakeholders to achieve common goals and ensure a smooth flow of materials and information throughout the supply chain network.

In summary, supply chain and operations management is the discipline that involves the coordination, planning, and execution of all activities involved in the production and delivery of goods and services. It encompasses supply chain management and operations management, working together to optimize efficiency, responsiveness, and customer satisfaction.

Key Components of Supply Chain and Operations Management

Supply chain and operations management consists of several key components that work together to ensure the smooth flow of materials, information, and resources across the entire value chain. These components include:

- Procurement: The process of sourcing and acquiring raw materials, goods, and services needed for production. This involves supplier selection, negotiation, and contract management.

- Production Planning: Determining the production requirements, scheduling resources, and optimizing the production process to meet customer demand efficiently. It involves capacity planning, production scheduling, and forecasting.

- Inventory Management: Ensuring the right quantity of products is available at the right time to meet customer demand. It involves managing stock levels, optimizing warehouse storage, and forecasting inventory needs.

- Logistics and Transportation: The movement of goods and materials from suppliers to manufacturing facilities, distribution centers, and ultimately to the end consumers. This component includes transportation management, shipment tracking, and managing transportation costs.

- Warehousing and Distribution: The storage, handling, and distribution of finished goods to customers. This component involves managing warehouses, optimizing order fulfillment, and coordinating distribution networks.

- Quality Control: Ensuring that products and services meet the required quality standards. This includes conducting inspections, implementing quality assurance processes, and continuous improvement initiatives.

- Supply Chain Analytics: The use of data and technology to analyze supply chain processes, identify opportunities for optimization, and make data-driven decisions. This component involves using advanced analytics, such as predictive modeling and machine learning, to improve supply chain performance.

These key components of supply chain and operations management are interconnected and depend on each other for efficient and effective functioning. By integrating and managing these components effectively, organizations can achieve better operational efficiency, reduced costs, improved customer satisfaction, and increased competitiveness in the market.

Importance of Supply Chain and Operations Management

Supply chain and operations management play a crucial role in the success and competitiveness of businesses in today’s global marketplace. Here are several reasons why supply chain and operations management are important:

- Cost Savings: Effective supply chain and operations management can lead to significant cost savings. By optimizing processes, reducing waste, and improving efficiency, organizations can reduce production costs, transportation costs, and inventory holding costs. This, in turn, can improve profit margins and overall financial performance.

- Customer Satisfaction: A well-managed supply chain ensures that products are delivered to customers in a timely and efficient manner. This leads to higher customer satisfaction and loyalty. Providing a seamless and positive customer experience can differentiate a business from its competitors and contribute to long-term success.

- Competitive Advantage: Supply chain and operations management can be a source of competitive advantage. Organizations with efficient and agile supply chains can respond quickly to changes in the market, adapt to customer demands, and introduce new products or services faster than their competitors. This helps them stay ahead in the market and gain a competitive edge.

- Risk Management: Supply chain and operations management involves identifying and managing various risks in the supply chain, such as supplier disruptions, demand fluctuations, and logistics challenges. By implementing risk mitigation strategies, businesses can reduce the impact of disruptions and ensure business continuity.

- Sustainability: Effective supply chain and operations management can contribute to sustainability efforts. By optimizing transportation routes, reducing carbon emissions, minimizing waste generation, and implementing responsible sourcing practices, organizations can reduce their environmental footprint and create a positive impact on society.

- Innovation: Supply chain and operations management provide opportunities for innovation and continuous improvement. By leveraging technology, data analytics, and automation, organizations can identify areas for improvement, streamline processes, and drive innovation throughout the supply chain.

In summary, supply chain and operations management are essential for organizations to achieve cost savings, improve customer satisfaction, gain a competitive advantage, manage risks, promote sustainability, and foster innovation. By strategically managing the flow of goods, information, and resources, businesses can optimize their operations and drive long-term success in today’s dynamic business environment.

Role of Supply Chain and Operations Managers

Supply chain and operations managers play a critical role in ensuring the smooth and efficient functioning of the entire supply chain and operations processes. Their responsibilities encompass various key areas, including:

- Strategic Planning: Supply chain and operations managers are responsible for developing and executing strategic plans that align with the overall business objectives. They analyze market trends, customer demands, and business goals to develop strategies that optimize supply chain performance and drive operational excellence.

- Supplier Management: Managing relationships with suppliers is crucial for supply chain managers. They select and evaluate suppliers, negotiate contracts, monitor performance, and ensure timely delivery of quality materials and services. Effective supplier management helps maintain a reliable and cost-effective supply chain.

- Inventory Control: Supply chain managers are responsible for managing inventory levels to meet customer demands while minimizing carrying costs. They implement inventory control techniques, such as ABC analysis, demand forecasting, and just-in-time (JIT) inventory management, to optimize inventory levels and reduce stockouts or excess inventory.

- Logistics Management: Ensuring the smooth flow of goods and materials is a vital responsibility of supply chain managers. They oversee transportation, distribution, and warehousing processes to ensure efficient movement of products from suppliers to customers. This involves optimizing transportation routes, managing logistics partners, and coordinating various logistics activities.

- Process Improvement: Supply chain and operations managers continually seek opportunities to improve processes and enhance operational performance. They analyze supply chain data, identify bottlenecks and inefficiencies, and implement process improvement initiatives, such as lean methodologies or Six Sigma, to streamline operations, reduce costs, and enhance productivity.

- Risk Management: Managing risks within the supply chain is a critical role of supply chain managers. They identify potential risks, develop risk mitigation strategies, and establish contingency plans to address disruptions, such as supplier failures, natural disasters, or geopolitical events. Effective risk management helps ensure business continuity and minimize supply chain disruptions.

- Collaboration and Communication: Supply chain and operations managers collaborate with various internal departments, such as procurement, production, sales, and customer service, to ensure alignment and coordination across functions. They also interact with external stakeholders, including suppliers, customers, and logistics partners, to build and maintain strong business relationships.

The role of supply chain and operations managers is multidimensional and requires strong analytical, problem-solving, leadership, and communication skills. They must be able to adapt to changing market conditions, leverage technology and data analytics, and make informed decisions to optimize supply chain performance, meet customer expectations, and drive operational excellence.

In summary, supply chain and operations managers are instrumental in managing the critical components of the supply chain, optimizing processes, reducing costs, managing risks, and fostering collaboration across the organization. Their role is vital in achieving overall supply chain efficiency, customer satisfaction, and business success.

Challenges in Supply Chain and Operations Management

Managing a complex supply chain and operations process comes with its own set of challenges. Supply chain and operations managers must navigate through these challenges to ensure the smooth functioning of the entire value chain. Here are some of the key challenges they face:

- Globalization and Complex Networks: With the increasing globalization of businesses, supply chains have become more extended and complex. Managing multiple suppliers, transportation networks, and distribution channels across different countries and regions presents challenges in terms of coordination, communication, and compliance with varying regulations.

- Supply Chain Disruptions: Disruptions such as natural disasters, political unrest, or supplier failures can have a major impact on the supply chain. Supply chain managers need to develop robust risk management strategies and contingency plans to mitigate the effects of these disruptions and ensure business continuity.

- Demand Volatility and Forecasting: Forecasting customer demand accurately is crucial for effective supply chain management. However, fluctuating demand patterns, seasonality, and market uncertainties pose challenges for demand forecasting. Inaccurate forecasts can lead to stockouts, excess inventory, or inefficiencies in production planning.

- Inventory Management: Balancing inventory levels to meet customer demands while minimizing carrying costs is a constant challenge. Maintaining optimal inventory levels requires careful inventory planning, monitoring, and establishing effective inventory control techniques to avoid stockouts or excess inventory.

- Supplier Management: Selecting and managing suppliers can be challenging. Ensuring a reliable supply of quality materials at competitive prices requires effective supplier evaluation, relationship management, and monitoring of supplier performance. Managing multiple suppliers across different locations adds complexity to the process.

- Technology and Data Integration: Incorporating technology and integrating data across the supply chain is crucial for efficient operations. However, implementing and integrating new technologies, such as supply chain management software or Internet of Things (IoT) devices, can be challenging. Ensuring data accuracy, security, and compatibility across different systems is also a challenge.

- Talent Development: Finding and retaining skilled talent in supply chain and operations management can be a challenge. The evolving nature of the field requires professionals with a diverse skill set, including data analytics, project management, and problem-solving skills. Developing and nurturing talent within the organization is crucial for supply chain success.

These challenges highlight the dynamic and complex nature of supply chain and operations management. By proactively addressing these challenges through effective planning, risk management, technology adoption, and talent development, supply chain and operations managers can overcome these hurdles and create resilient and efficient supply chains.

Strategies for Effective Supply Chain and Operations Management

Effective supply chain and operations management requires a strategic approach to optimize processes, reduce costs, and enhance overall efficiency. Here are some key strategies that can help achieve these objectives:

- Collaboration and Partnership: Foster collaboration and build strong relationships with suppliers, customers, and other stakeholders in the supply chain. Establishing partnerships based on trust, transparency, and mutual benefit can lead to better communication, shared information, and collaborative problem-solving.

- Data-Driven Decision Making: Utilize data analytics and technology to gather, analyze, and interpret supply chain data. This enables informed decision-making, accurate demand forecasting, and identification of areas for process improvement. Leveraging technologies such as artificial intelligence and machine learning can provide valuable insights for optimization.

- Continuous Improvement: Embrace a culture of continuous improvement within the organization. Encourage employees to identify areas for improvement, streamline processes, and implement best practices such as lean methodologies or Six Sigma. Regularly review and assess performance metrics to identify bottlenecks and inefficiencies.

- Risk Management: Develop comprehensive risk management strategies to mitigate supply chain disruptions. Identify potential risks and establish contingency plans to minimize the impact of disruptions. This may involve diversifying suppliers, implementing backup production facilities, or establishing alternative transportation routes.

- Supplier Relationship Management: Implement effective supplier management practices. This includes selecting and evaluating suppliers based on performance metrics, developing long-term relationships, and collaborating with suppliers for joint process improvement initiatives. Regularly review supplier performance to ensure alignment with organizational goals.

- Technology Adoption: Embrace technology to streamline supply chain operations. Implement supply chain management software, warehouse management systems, and transportation management systems to automate processes, improve visibility, and enhance efficiency. Explore emerging technologies such as blockchain, IoT, and robotic process automation to unlock further opportunities for optimization.

- Customer-Centric Focus: Prioritize customer satisfaction by aligning supply chain processes with customer needs. Gather customer feedback, analyze market trends, and customize supply chain processes to meet changing customer demands. Enhance responsiveness and adaptability to deliver products and services that exceed customer expectations.

By implementing these strategies, organizations can achieve a more effective and efficient supply chain and operations management system. These strategies enable businesses to optimize processes, reduce costs, manage risks, and enhance customer satisfaction in today’s competitive business environment.

Technologies Impacting Supply Chain and Operations Management

Advancements in technology have revolutionized the field of supply chain and operations management. The adoption of innovative technologies is crucial for businesses aiming to optimize processes, enhance visibility, and gain a competitive edge. Here are some key technologies that are significantly impacting supply chain and operations management:

- Supply Chain Management (SCM) Software: SCM software provides end-to-end visibility and control over supply chain processes. It facilitates demand forecasting, inventory management, order tracking, and collaboration with suppliers and customers. With features such as real-time data analytics and automation, SCM software enables proactive decision-making and streamlines operations.

- Internet of Things (IoT): IoT devices, such as sensors and RFID tags, enable real-time tracking and monitoring of goods, inventory, and equipment. IoT enables enhanced supply chain visibility, inventory accuracy, and predictive maintenance capabilities. Connected devices provide valuable data for optimizing processes, improving product quality, and reducing costs.

- Blockchain: Blockchain technology offers enhanced transparency, traceability, and security in supply chain operations. It enables secure and decentralized record-keeping, authentication of transactions, and tracking of goods throughout the supply chain. Blockchain provides trust and prevents fraud, improving efficiency and reducing costs in areas such as supply chain financing and product provenance.

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML technologies enable intelligent decision-making and automation in supply chain management. They analyze vast amounts of data to identify patterns, predict demand, optimize routing, and improve forecasting accuracy. AI-powered chatbots and virtual assistants also enhance customer service and communication.

- Robotics and Automation: Robotics and automation technologies enhance efficiency and accuracy in various supply chain processes. Automated sorting systems, robotic picking and packing, and autonomous vehicles optimize warehouse operations and reduce human errors. Robotic process automation (RPA) automates repetitive tasks, freeing up human resources for more strategic activities.

- Cloud Computing: Cloud-based platforms offer scalability, flexibility, and collaboration capabilities in supply chain and operations management. Cloud-based solutions provide real-time data access, facilitate collaboration with partners, and enable seamless integration of data across different systems. Cloud computing also enhances resilience and reduces infrastructure costs.

- Big Data Analytics: Big data analytics enables organizations to gain insights from the massive amount of data generated by supply chain processes. Analyzing data helps in identifying trends, optimizing inventory levels, improving supplier performance, and enhancing overall supply chain visibility. Predictive analytics enables proactive decision-making and risk management.

These technologies have the potential to transform supply chain and operations management by improving efficiency, enhancing visibility, reducing costs, and enabling better decision-making. By embracing and leveraging these technologies, businesses can gain a competitive advantage and achieve operational excellence in the rapidly evolving landscape of supply chain management.

Future Trends in Supply Chain and Operations Management

The field of supply chain and operations management is constantly evolving, driven by technological advancements, changing customer expectations, and global market dynamics. Here are some key future trends that are expected to shape the landscape of supply chain and operations management:

- Supply Chain Digitization: The digital transformation of supply chains will continue to gain momentum. This includes the adoption of technologies such as IoT, AI, blockchain, and cloud computing to enhance visibility, connectivity, and automation. Digitization enables real-time data exchange, predictive analytics, and seamless collaboration, leading to more efficient and agile supply chains.

- E-commerce and Last Mile Delivery: The growth of e-commerce has changed customer expectations, placing greater emphasis on last mile delivery. To meet these demands, supply chains will need to optimize logistics, implement innovative delivery methods (e.g., drones, autonomous vehicles), and enhance order fulfillment processes to provide fast and convenient delivery experiences.

- Sustainability and Social Responsibility: Environmental sustainability and social responsibility will become integral to supply chain and operations management. Organizations will focus on reducing carbon emissions, implementing circular economy practices, and ensuring responsible sourcing and ethical practices throughout the supply chain. Sustainable strategies will be crucial for meeting customer expectations and regulatory requirements.

- Supply Chain Resilience: With increasing global uncertainties and supply chain disruptions, resilience will become a key focus for supply chain management. This includes developing robust risk management strategies, building agile and flexible supply chains, diversifying suppliers, and implementing business continuity plans to respond to disruptions effectively and ensure uninterrupted operations.

- Advanced Analytics and Predictive Forecasting: The use of advanced analytics and predictive forecasting will continue to evolve in supply chain management. By leveraging big data, AI, and ML technologies, organizations can gain deeper insights into demand patterns, optimize inventory levels, improve forecasting accuracy, and proactively identify potential disruptions or bottlenecks.

- Collaborative and Connected Supply Chains: Collaboration will be a key driver of supply chain success. Supply chains will become more interconnected and collaborative, with strategic partnerships, shared data, and integrated processes. This will enable end-to-end visibility, seamless information exchange, and synchronized decision-making across the supply chain network.

- Talent Management and Skill Development: As supply chain management becomes more complex, organizations will need to invest in talent development, fostering a diverse skill set. This includes skills in data analytics, digital technologies, risk management, and strategic thinking. Continuous learning and professional development will be essential to stay ahead in the rapidly evolving field.

These future trends indicate a shift towards more intelligent, sustainable, and customer-centric supply chains. Embracing these trends will enable organizations to thrive in a highly competitive and rapidly changing business environment.

Conclusion

Supply chain and operations management are integral to the success of any organization. The effective management of the entire value chain, from sourcing to delivery, is crucial for optimizing efficiency, reducing costs, enhancing customer satisfaction, and gaining a competitive edge. As the business landscape continues to evolve, supply chain and operations managers must adapt to technological advancements, changing customer expectations, and global market dynamics.

In this article, we explored the definition of supply chain and operations management and the key components that make up this discipline. We also examined the importance of effective supply chain management in achieving cost savings, customer satisfaction, competitive advantage, risk management, sustainability, and innovation.

Furthermore, we delved into the role of supply chain and operations managers, highlighting their responsibilities in strategic planning, supplier management, inventory control, logistics, process improvement, risk management, and collaboration.

We also discussed the challenges that supply chain and operations managers face, including globalization, supply chain disruptions, demand volatility, inventory management, supplier management, technology integration, and talent development. However, with effective strategies such as collaboration, data-driven decision making, continuous improvement, risk management, supplier relationship management, technology adoption, and customer-centric focus, these challenges can be overcome.

Lastly, we explored the emerging technologies that are impacting supply chain and operations management, including supply chain management software, IoT, blockchain, AI, robotics, cloud computing, and big data analytics. Embracing these technologies enables organizations to optimize processes, enhance visibility, and improve decision-making capabilities.

Looking ahead, we discussed the future trends expected to shape supply chain and operations management, including supply chain digitization, e-commerce, sustainability, supply chain resilience, advanced analytics, collaboration, and talent development.

In conclusion, effective supply chain and operations management is vital for organizations to thrive in today’s complex and competitive business landscape. By continuously adapting to evolving trends and leveraging technology, organizations can build efficient, resilient, and customer-centric supply chains, thus driving long-term success and growth.