Finance

What Is A Supply Chain Network?

Published: October 19, 2023

Learn about the finance aspect of a supply chain network and how it impacts businesses. Explore the importance of efficient financial management in optimizing supply chain operations.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for LiveWell, at no extra cost. Learn more)

Table of Contents

- Introduction

- Definition of Supply Chain Network

- Components of a Supply Chain Network

- Nodes in a Supply Chain Network

- Links in a Supply Chain Network

- Functions of a Supply Chain Network

- Importance of a Supply Chain Network

- Challenges in Managing a Supply Chain Network

- Key Considerations for Designing a Supply Chain Network

- Strategies for Optimizing a Supply Chain Network

- Case Studies of Successful Supply Chain Networks

- Conclusion

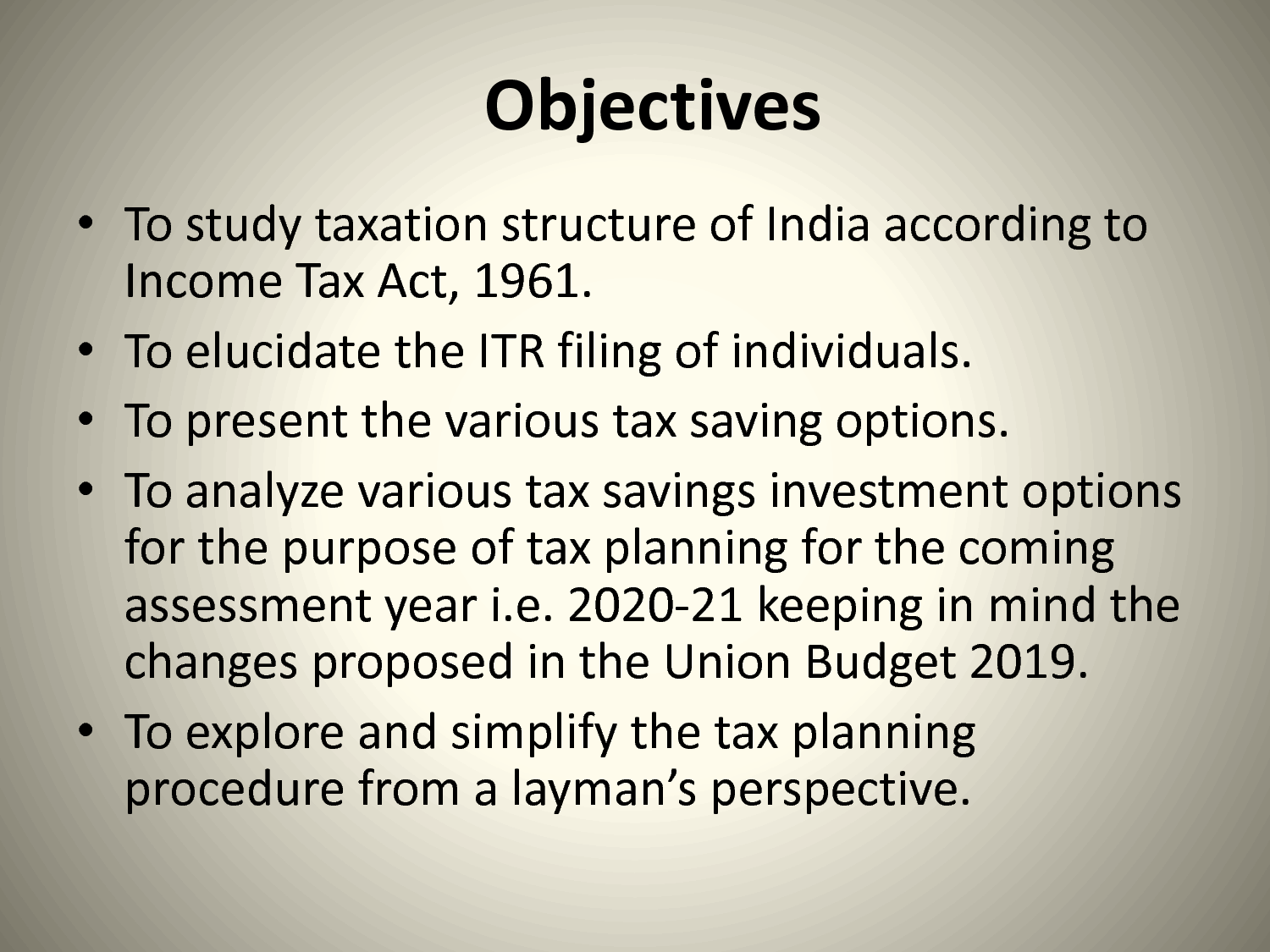

Introduction

A supply chain network is a crucial component of any business operation involved in the production, distribution, and delivery of goods or services. It refers to the interconnected system of organizations, resources, activities, and technology that work together to bring a product or service from the supplier to the end consumer.

The supply chain network plays a vital role in ensuring the seamless flow of materials, information, and financial transactions across various stages, including procurement, manufacturing, warehousing, transportation, and retail. It involves coordinating and synchronizing the activities of suppliers, manufacturers, distributors, retailers, and customers to efficiently meet customer demands and enhance the overall performance of the supply chain.

In today’s globalized and highly competitive business landscape, a well-designed and properly managed supply chain network is essential for companies to stay competitive and meet customer expectations. It allows organizations to optimize their operations, reduce costs, improve efficiency, enhance customer satisfaction, and gain a competitive advantage.

In this article, we will explore the concept of a supply chain network in depth, discussing its components, functions, importance, challenges, and strategies for optimization. We will also analyze real-life case studies of successful supply chain networks to provide practical insights and guidance.

By the end of this article, you will have a comprehensive understanding of what a supply chain network is and how it can contribute to the success of a business. Whether you are a supply chain professional, a business owner, or simply curious about the behind-the-scenes workings of the products you use, this article will provide valuable insights into the fascinating world of supply chain management.

Definition of Supply Chain Network

A supply chain network encompasses the interconnected web of organizations, facilities, logistics, processes, and resources involved in the production, distribution, and delivery of goods or services. It serves as the backbone of a company’s operations, enabling the smooth flow of materials, information, and finances from raw material suppliers to end customers.

At its core, a supply chain network is designed to create value by efficiently and effectively meeting customer demands while minimizing costs and maximizing profitability. It involves the strategic integration and coordination of key activities such as procurement, manufacturing, inventory management, transportation, warehousing, and customer service.

The primary goal of a supply chain network is to ensure that the right products reach the right places at the right time. This requires careful planning and synchronization, as well as effective communication and collaboration among the various entities within the network.

Supply chain networks can vary in complexity and scope depending on the nature of the industry, the size of the company, and the geographic reach of the market. They can span multiple countries, involve numerous suppliers and distributors, and encompass different modes of transportation, such as air, sea, rail, or road.

In today’s digital age, supply chain networks are increasingly leveraging advanced technologies like automation, artificial intelligence, data analytics, and Internet of Things (IoT) devices to optimize operations and enhance visibility across the network. This enables real-time tracking, improved forecasting, and better decision-making, resulting in increased efficiency and responsiveness.

Overall, a well-designed and effectively managed supply chain network is essential for companies to thrive in today’s competitive business landscape. It allows organizations to reduce costs, minimize risks, improve customer satisfaction, and gain a competitive advantage by creating a lean, agile, and resilient supply chain.

Components of a Supply Chain Network

A supply chain network consists of various components that work together to ensure the smooth and efficient flow of goods and services. These components play distinct roles in the overall operation of the network. Let’s explore the key components of a supply chain network:

- Suppliers: Suppliers are the sources from which a company procures raw materials, components, or finished goods. They form the starting point of the supply chain network and play a crucial role in determining the quality, availability, and cost of inputs for production.

- Manufacturers: Manufacturers transform raw materials and components into finished products. They are responsible for production planning, scheduling, quality control, and ensuring that the products meet the desired specifications.

- Distributors: Distributors or wholesalers are intermediaries between manufacturers and retailers. They purchase large quantities of products from manufacturers and sell them in smaller quantities to retailers or end customers. Distributors help in reaching products to different geographic locations efficiently.

- Retailers: Retailers are the final players in the supply chain network who sell products directly to end customers. They can range from brick-and-mortar stores to e-commerce platforms. Retailers play a critical role in understanding customer demand, managing inventory, and providing a seamless buying experience.

- Transportation: Transportation is a vital component that facilitates the movement of goods from one point to another within the supply chain network. It involves selecting the appropriate mode of transportation, such as trucks, ships, planes, or trains, and optimizing routes and delivery schedules to ensure timely and cost-effective delivery.

- Warehousing: Warehousing involves the storage of goods at different stages of the supply chain. Warehouses serve as distribution centers, enabling efficient inventory management, order fulfillment, and product consolidation. They play a crucial role in minimizing lead times and balancing supply and demand.

- Information Systems: Information systems are the backbone of a supply chain network. They facilitate the flow of information and data across all components of the network, enabling real-time visibility, coordination, and decision-making. Robust systems for demand forecasting, inventory management, and tracking are essential for optimizing the supply chain.

These components work together in a synchronized manner to ensure the smooth functioning of the supply chain network. By effectively managing these components and optimizing their interactions, companies can improve efficiency, reduce costs, and enhance customer satisfaction.

Nodes in a Supply Chain Network

In a supply chain network, nodes refer to the various locations or entities where the flow of goods, information, and money converge. These nodes play a critical role in shaping the structure and efficiency of the supply chain network. Let’s explore the key nodes in a supply chain network:

- Supplier Nodes: Supplier nodes are the starting points of the supply chain network. They represent the locations or entities from which a company procures raw materials, components, or finished goods. Supplier nodes can be located locally or globally, depending on the sourcing strategy of the company.

- Manufacturing Nodes: Manufacturing nodes consist of production facilities where raw materials and components are transformed into finished products. These nodes involve various operations such as assembly, fabrication, packaging, and quality control. Manufacturing nodes can be owned by the company or outsourced to contract manufacturers.

- Distribution Centers: Distribution centers act as intermediate nodes within the supply chain network. They are strategically positioned to receive, store, and process inventory before it is sent to retailers or end customers. Distribution centers enable efficient inventory management, order fulfillment, and product consolidation.

- Retail Nodes: Retail nodes represent the locations where products are sold directly to end customers. These can include brick-and-mortar stores, e-commerce platforms, or other sales channels. Retail nodes play a crucial role in understanding customer demand, managing inventory, and providing a seamless buying experience.

- Transportation Hubs: Transportation hubs serve as connecting nodes within the supply chain network. They can include ports, airports, railway terminals, or major highways. Transportation hubs facilitate the efficient movement of goods from one location to another, enabling speedy and cost-effective transportation.

- Customer Nodes: Customer nodes represent the end customers or consumers of the products within the supply chain network. Understanding customer preferences, behavior, and demand patterns is essential for effective supply chain management. Customer nodes provide valuable feedback and supply chain visibility through order placement, payment, and post-sales activities.

These nodes are interconnected, and the effectiveness of the supply chain network depends on how well these nodes are coordinated and synchronized. Efficient management of nodes leads to improved inventory control, enhanced order fulfillment, reduced lead times, and better customer service.

It is important for companies to strategically locate these nodes to ensure the optimal flow of goods and minimize logistical costs. Analyzing factors such as proximity to suppliers, market demand, transportation infrastructure, and operational efficiency is crucial in determining the optimal node locations within the supply chain network.

Links in a Supply Chain Network

In a supply chain network, links represent the connections and relationships between the various nodes and components of the network. These links are essential for the smooth flow of materials, information, and finances throughout the supply chain. Let’s explore the key links in a supply chain network:

- Supplier Links: Supplier links connect the suppliers to the rest of the supply chain network. These links involve activities such as sourcing, negotiating contracts, placing orders, and managing supplier relationships. Effective supplier links ensure a reliable and consistent supply of raw materials or components to support production.

- Production Links: Production links connect the manufacturing nodes within the supply chain network. These links involve activities such as production planning, scheduling, inventory control, quality assurance, and process optimization. Well-managed production links ensure the efficient transformation of raw materials into finished products.

- Transportation Links: Transportation links connect the various nodes in the supply chain network through the movement of goods. These links involve selecting the appropriate mode of transportation, optimizing routes, managing carriers, tracking shipments, and coordinating delivery schedules. Transportation links play a crucial role in ensuring timely and cost-effective delivery of products.

- Distribution Links: Distribution links connect the distribution centers or warehouses to the retailers or end customers. These links involve activities such as order management, inventory allocation, order fulfillment, and product delivery. Well-established distribution links enable efficient inventory management, timely order processing, and seamless customer service.

- Information Links: Information links are crucial for the exchange of data and communication within the supply chain network. These links involve the use of technology, such as enterprise resource planning (ERP) systems, electronic data interchange (EDI), and supply chain management software, to facilitate real-time visibility, coordination, and decision-making. Information links enable accurate demand forecasting, improved inventory management, and effective collaboration among the network participants.

- Financial Links: Financial links connect the financial transactions and flows within the supply chain network. These links involve activities such as invoicing, payment processing, credit terms, and financing arrangements. Efficient financial links ensure smooth cash flow and financial stability within the supply chain network.

These links are interconnected and rely on each other for the effective functioning of the supply chain network. Strong and well-coordinated links result in reduced lead times, improved inventory accuracy, enhanced customer satisfaction, and cost savings through streamlined operations and improved decision-making.

Companies should focus on strengthening these links by fostering collaboration, implementing advanced technologies, and establishing clear communication channels. By optimizing and integrating these links, companies can achieve a more resilient and agile supply chain network that can adapt to changing market conditions and deliver a competitive edge.

Functions of a Supply Chain Network

A supply chain network performs a wide range of functions that are essential for the smooth operation and effective management of the overall supply chain. These functions encompass various activities and processes that contribute to the successful flow of materials, information, and finances. Let’s explore the key functions of a supply chain network:

- Procurement: Procurement involves sourcing and acquiring the necessary raw materials, components, or finished products from suppliers. It includes activities such as supplier selection, negotiation, purchase order placement, and contract management. Effective procurement ensures a reliable and cost-effective supply of inputs for production.

- Production: Production encompasses the transformation of raw materials and components into finished products. It involves activities such as planning, scheduling, manufacturing, quality control, and inventory management. Effective production ensures efficient and timely production processes that meet the desired specifications while minimizing costs.

- Inventory Management: Inventory management involves the control and optimization of stock levels at various stages in the supply chain network, including raw materials, work-in-progress, and finished goods. It includes activities such as demand forecasting, stock replenishment, stock rotation, and order fulfillment. Effective inventory management ensures balanced supply and demand, reduces carrying costs, and minimizes stockouts or excess inventory.

- Warehousing and Distribution: Warehousing and distribution functions involve the storage, handling, and movement of goods within the supply chain network. It includes activities such as receiving, storing, order picking, packing, and shipping. Effective warehousing and distribution ensure efficient inventory control, order accuracy, and timely delivery to customers.

- Transportation: Transportation function involves the movement of goods from one location to another within the supply chain network. It includes selecting the appropriate mode of transportation, optimizing routes, managing carriers, and tracking shipments. Effective transportation ensures timely and cost-effective delivery of products while meeting customer expectations.

- Information Management: Information management function encompasses the collection, analysis, and dissemination of data and information within the supply chain network. It includes activities such as demand forecasting, supply chain visibility, order processing, and performance measurement. Effective information management enables real-time visibility and collaboration, improves decision-making, and enhances overall supply chain performance.

- Customer Service: Customer service function involves meeting customer expectations and ensuring satisfaction throughout the supply chain process. It includes activities such as order management, order tracking, returns management, and after-sales support. Effective customer service fosters strong relationships with customers, enhances loyalty, and drives repeat business.

- Continuous Improvement: Continuous improvement function focuses on identifying opportunities for enhancing efficiency, reducing waste, and improving overall supply chain performance. It involves activities such as process optimization, performance measurement, benchmarking, and implementing best practices. Effective continuous improvement fosters innovation, agility, and adaptability within the supply chain network.

These functions are interconnected and need to be efficiently managed to ensure the smooth and efficient operation of the supply chain network. By effectively performing these functions, companies can achieve cost savings, improve operational efficiency, enhance customer satisfaction, and gain a competitive edge in the marketplace.

Importance of a Supply Chain Network

A well-designed and properly managed supply chain network is of utmost importance for businesses across industries. It plays a pivotal role in ensuring operational efficiency, cost optimization, and customer satisfaction. Let’s explore the key reasons why a supply chain network is important:

- Improved Efficiency: A well-structured supply chain network enables the efficient flow of materials, information, and finances. It streamlines processes, eliminates bottlenecks, and reduces lead times, resulting in improved operational efficiency. By optimizing inventory levels, minimizing stockouts, and enhancing order fulfillment, businesses can reduce costs, increase productivity, and achieve better resource allocation.

- Cost Optimization: An effective supply chain network helps businesses identify cost-saving opportunities and implement strategies to minimize expenses. By optimizing transportation routes, consolidating shipments, and managing inventory effectively, companies can reduce transportation costs, warehousing expenses, and carrying costs. Cost optimization within the supply chain network leads to improved profitability and a competitive advantage in the market.

- Enhanced Customer Satisfaction: A well-functioning supply chain network plays a crucial role in meeting customer expectations and delivering superior customer service. By ensuring timely and accurate product delivery, providing real-time order tracking, and offering responsive customer support, businesses can enhance customer satisfaction. A satisfied customer is more likely to become a repeat customer, leading to increased sales and brand loyalty.

- Increased Flexibility: An agile and robust supply chain network enables businesses to respond effectively to changing market demands and unforeseen disruptions. By having backup suppliers, multiple distribution centers, and adaptable production capabilities, businesses can quickly adjust to fluctuations in demand, natural disasters, or supply disruptions. Increased flexibility within the supply chain network minimizes risks and enhances the company’s ability to navigate challenging situations.

- Improved Collaboration: A supply chain network requires collaboration and coordination among various stakeholders, including suppliers, manufacturers, distributors, and retailers. Effective communication, information sharing, and joint problem-solving can lead to improved collaboration and better relationships among the network participants. Enhanced collaboration fosters transparency, trust, and shared goals, resulting in improved supply chain performance.

- Market Expansion: A well-designed supply chain network enables businesses to expand into new markets and reach customers in distant or international locations. By strategically positioning suppliers, production facilities, distribution centers, and retail outlets, companies can enter new markets, penetrate different geographical regions, and tap into new customer segments. Market expansion through a well-optimized supply chain network can drive business growth and increase market share.

- Competitive Advantage: In today’s highly competitive business landscape, a well-managed supply chain network can provide a significant competitive advantage. It enables businesses to differentiate themselves by offering faster delivery times, higher product availability, better customer service, and lower costs compared to competitors. A competitive supply chain network can attract customers, win new business opportunities, and establish the company as a leader in the industry.

Overall, a robust and efficient supply chain network is crucial for businesses seeking to improve operational performance, reduce costs, enhance customer satisfaction, and gain a competitive edge in the market. It serves as a strategic asset that drives business success and enables companies to navigate the complexities and challenges of the modern business landscape.

Challenges in Managing a Supply Chain Network

Managing a supply chain network can be a complex undertaking due to the numerous challenges and complexities involved. These challenges can impact various aspects of the supply chain and require careful planning, effective strategies, and continuous monitoring. Let’s explore some of the key challenges in managing a supply chain network:

- Demand Forecasting: Accurately forecasting demand is a continual challenge for businesses. Fluctuating consumer preferences, market uncertainties, and unpredictable external factors can lead to demand disruptions. Inaccurate demand forecasts can result in excess inventory or stockouts, affecting overall supply chain efficiency.

- Supply Chain Visibility: Gaining end-to-end visibility over the supply chain network is crucial but often challenging. Lack of visibility can result in information gaps, delayed responses to disruptions, and inefficiencies in decision-making. Achieving supply chain visibility requires integrating systems, leveraging technology, and fostering collaboration among network participants.

- Supply Chain Risk: Supply chains are vulnerable to various risks, including natural disasters, geopolitical events, supplier disruptions, and changes in government regulations. These risks can impact the availability of raw materials, transportation routes, or delivery schedules. Managing and mitigating supply chain risks requires proactive risk assessments, contingency planning, and building resilient supplier relationships.

- Inventory Management: Balancing inventory levels to meet customer demand while minimizing holding costs is a common challenge. Overstocked inventory ties up capital and increases the risk of obsolescence, while insufficient inventory leads to stockouts and dissatisfied customers. Effective inventory management involves demand forecasting, optimizing reorder points, and leveraging technology for real-time visibility.

- Supplier Relationship Management: Building and maintaining strong relationships with suppliers is crucial for supply chain success. However, challenges such as supplier reliability, quality control, and alignment of objectives can impact supplier relationships. Effective supplier relationship management involves collaboration, clear communication, performance monitoring, and mutually beneficial partnerships.

- Changing Customer Expectations: Customer expectations are constantly evolving, driven by factors such as technology advancements, e-commerce, and increased emphasis on sustainability and personalized experiences. Adapting the supply chain to meet these changing expectations requires agility, optimization of last-mile delivery, and investment in customer-centric technologies.

- Technology Adoption: Embracing and integrating technology within the supply chain network can be a challenge for organizations. Implementing systems such as enterprise resource planning (ERP), warehouse management systems (WMS), or advanced analytics require investments, training, and overcoming resistance to change. However, technology adoption is critical for enhancing visibility, automation, data analysis, and overall supply chain effectiveness.

- Operational Complexity: Supply chain networks can become increasingly complex, especially with global sourcing, multi-tiered distribution, and multiple product SKUs. Managing the intricacies of these operations, coordinating activities across various network nodes, and optimizing processes can be challenging. Efficient supply chain network design, process simplification, and performance monitoring are essential to tackle operational complexity.

Successfully managing a supply chain network requires a proactive and dynamic approach to address these challenges. By adopting effective strategies, leveraging technology, fostering collaboration, and embracing continuous improvement, businesses can navigate these challenges and build a resilient and competitive supply chain network.

Key Considerations for Designing a Supply Chain Network

The design of a supply chain network is a critical process that determines the efficiency, flexibility, and overall performance of the supply chain. It involves making strategic decisions about the structure, locations, and connections within the network. Several key considerations should be taken into account when designing a supply chain network:

- Customer Demand: Understanding customer demand patterns, preferences, and expectations is crucial for designing an effective supply chain network. Analyzing historical data, conducting market research, and considering factors such as seasonality and regional variations can help align the network with customer requirements.

- Network Footprint: Determining the optimal number and location of facilities within the supply chain network is essential. This includes decisions on the number of manufacturing plants, distribution centers, warehouses, and retail outlets. Factors such as proximity to suppliers, customers, transportation infrastructure, and market potential need to be considered to minimize transportation costs and lead times.

- Transportation Efficiency: Evaluating transport options and optimizing transportation routes are critical considerations. Choosing the right mode of transportation (e.g., road, rail, air, or sea) based on cost, transit times, and product characteristics can significantly impact the supply chain network’s efficiency. Mapping out transportation lanes and optimizing delivery schedules can further enhance transportation efficiency.

- Supplier Management: Building a robust supplier base and cultivating strong relationships with suppliers are key components of supply chain network design. Assessing suppliers based on quality, reliability, flexibility, and cost factors is crucial. Collaboration with suppliers and establishing clear communication channels can lead to improved sourcing, reduced lead times, and better pricing.

- Technology Integration: Integrating technology platforms and systems is an essential consideration for a modern supply chain network. Implementing technologies such as enterprise resource planning (ERP), warehouse management systems (WMS), transportation management systems (TMS), and real-time tracking tools can enhance visibility, streamline processes, and enable data-driven decision-making.

- Risk Mitigation: Assessing and mitigating supply chain risks should be an integral part of network design. Identifying vulnerabilities, establishing contingency plans, and diversifying suppliers and transportation routes can help mitigate risks such as natural disasters, geopolitical events, or disruptions in the supply chain. Building a resilient network that can adapt to unforeseen circumstances is crucial.

- Sustainability: Designing a supply chain network with sustainability considerations can provide long-term benefits. Evaluating the environmental impact of transportation options, optimizing packaging to minimize waste, and collaborating with suppliers who adhere to sustainable practices can contribute to a greener and socially responsible network.

- Performance Monitoring: Establishing key performance indicators (KPIs) and implementing a robust performance monitoring system is essential for evaluating and optimizing the supply chain network’s effectiveness. Tracking metrics such as on-time delivery, inventory turnover, customer satisfaction, and overall cost can provide insights to drive continuous improvement efforts.

By carefully considering these factors, businesses can design a supply chain network that is aligned with customer demands, efficient in its operations, resilient to disruptions, and capable of providing a competitive advantage in the market.

Strategies for Optimizing a Supply Chain Network

Optimizing a supply chain network involves continuously improving its efficiency, responsiveness, and overall performance. By implementing effective strategies, businesses can streamline processes, reduce costs, enhance customer satisfaction, and gain a competitive edge. Let’s explore some key strategies for optimizing a supply chain network:

- Collaborative Planning: Foster collaboration and information sharing among network partners to enhance planning and ensure better demand forecasting accuracy. Collaborative planning improves inventory management, reduces stockouts, and minimizes the bullwhip effect.

- Lean Principles: Apply lean principles to eliminate waste, reduce lead times, and improve overall efficiency. Techniques such as just-in-time (JIT) production, continuous improvement, and value stream mapping can help optimize the supply chain network while reducing costs.

- Network Optimization: Use advanced analytics and optimization models to optimize the network design. Analyze factors such as facility locations, transportation routes, inventory placement, and production capacities. This can lead to cost savings, improved delivery times, and enhanced customer service.

- Supplier Collaboration: Establish strong relationships with suppliers and collaborate on joint initiatives. This can include sharing demand forecasts, conducting joint capacity planning, and implementing vendor-managed inventory (VMI) programs. Supplier collaboration enhances supply chain visibility, reduces lead times, and improves overall supply chain performance.

- Technology Integration: Leverage technology solutions to automate processes, improve visibility, and enhance decision-making. Implementing systems such as enterprise resource planning (ERP), warehouse management systems (WMS), and transportation management systems (TMS) can streamline operations and improve overall supply chain efficiency.

- Continuous Improvement: Embrace a culture of continuous improvement to drive ongoing efficiency gains and performance enhancements. Encourage cross-functional teams to identify and implement process improvements, adopt best practices, and regularly review and update supply chain strategies.

- Risk Management: Implement strategies to identify, assess, and mitigate supply chain risks. This can include diversifying suppliers, creating contingency plans, and establishing risk management protocols. Proactive risk management reduces the impact of disruptions and enhances supply chain resilience.

- Demand-Driven Approach: Adopt a demand-driven approach to align supply chain activities with real-time customer demand. This involves leveraging technologies such as demand sensing and demand-driven replenishment. By synchronizing supply and demand, businesses can reduce costs, improve customer satisfaction, and minimize inventory levels.

- Sustainable Practices: Incorporate sustainability considerations into supply chain operations. This can involve reducing carbon footprint through optimized transportation, using eco-friendly packaging materials, and collaborating with suppliers who adhere to sustainable practices. Sustainability not only benefits the environment but can also lead to cost savings and improved brand reputation.

By implementing these strategies, businesses can optimize their supply chain networks, drive operational efficiencies, reduce costs, and deliver superior customer value. It is important to regularly evaluate and adjust these strategies based on changing market conditions, customer expectations, and technological advancements to maintain a competitive edge in today’s dynamic business landscape.

Case Studies of Successful Supply Chain Networks

Examining real-life case studies can provide valuable insights into the strategies and practices that contribute to successful supply chain networks. Let’s explore a few examples of companies that have achieved remarkable success in optimizing their supply chain networks:

- Amazon: Amazon has revolutionized supply chain management by leveraging advanced technologies and innovative strategies. Its supply chain network is designed to fulfill millions of customer orders with speed and efficiency. Amazon’s network comprises a vast network of fulfillment centers strategically located near major population centers. It uses advanced algorithms and real-time data to optimize inventory placement, transportation routes, and delivery schedules. Through investments in automation, robotics, and predictive analytics, Amazon has achieved remarkable operational efficiency, enabling it to offer fast and reliable delivery to customers worldwide.

- Walmart: Walmart is known for its highly efficient and cost-effective supply chain network. The company’s network is designed to minimize costs while ensuring product availability. Walmart uses a hub-and-spoke distribution model, where large regional distribution centers serve as hubs for smaller satellite facilities. This network enables efficient sourcing, transportation, and inventory management. By implementing advanced technologies for demand forecasting, inventory control, and supply chain analytics, Walmart has achieved industry-leading efficiency, reduced stockouts, and consistently delivered low prices to its customers.

- Zara: Zara, a global fashion retailer, has gained a competitive advantage through its unique supply chain network. Zara operates a fast-fashion model that emphasizes speed and responsiveness to changing customer preferences. Its supply chain network is vertically integrated, with in-house design, production, and distribution capabilities. Zara’s network enables quick replenishment of inventory, with new designs reaching stores within weeks. By leveraging real-time sales data and customer feedback, Zara can rapidly adapt its production and distribution processes, ensuring that customers have access to the latest fashion trends, leading to high customer satisfaction and increased sales.

- Procter & Gamble (P&G): P&G has established a highly collaborative supply chain network that spans across its global operations. The company’s network emphasizes close collaboration with suppliers and customers to ensure efficient demand planning and order fulfillment. P&G uses advanced data analytics and demand sensing technologies to anticipate consumer demand and synchronize production and distribution accordingly. By implementing vendor-managed inventory (VMI) programs and sharing real-time data with suppliers, P&G has significantly improved inventory management, reduced stockouts, and enhanced customer service.

- Tesla: Tesla, the electric vehicle manufacturer, has disrupted the automotive industry with its unique supply chain network. Tesla has vertically integrated its supply chain, tightly controlling critical components such as batteries and electric drivetrains. By establishing its Gigafactories, Tesla has achieved economies of scale in battery production and reduced dependence on suppliers. Through direct sales to customers and a limited network of retail stores, Tesla has streamlined its distribution channels and customer engagement. Tesla’s agile supply chain network enables quick response to market demand and efficient production of electric vehicles.

These case studies demonstrate the importance of strategic planning, innovative technologies, collaboration, and adaptability in building successful supply chain networks. By studying these examples and understanding the strategies employed by these companies, businesses can gain valuable insights to optimize their own supply chain networks and achieve supply chain excellence.

Conclusion

A well-designed and efficiently managed supply chain network is essential for businesses to thrive in today’s competitive and dynamic market. It enables the seamless flow of materials, information, and finances, ensuring that products reach customers in a timely and cost-effective manner. Throughout this article, we have explored the various components, functions, and challenges associated with supply chain networks.

The supply chain network encompasses nodes and links that connect suppliers, manufacturers, distributors, retailers, and customers. It involves strategic considerations such as demand forecasting, network design, transportation efficiency, and technology integration. By optimizing these elements, businesses can achieve enhanced operational efficiency, reduced costs, improved customer satisfaction, and a competitive advantage.

Effective supply chain network management requires collaboration, flexibility, and continuous improvement. It involves strategies such as collaborative planning, lean principles, network optimization, and supplier collaboration. Embracing technologies like ERP systems, WMS, TMS, and real-time tracking tools empowers businesses with better visibility and data-driven decision-making capabilities.

Real-life case studies of successful supply chain networks highlight the importance of factors such as advanced analytics, vertical integration, collaborative relationships, and customer-centricity. Companies like Amazon, Walmart, Zara, P&G, and Tesla have demonstrated the power of strategic network design, innovative technologies, and customer-focused approaches in achieving supply chain excellence.

In conclusion, understanding and optimizing the supply chain network is crucial for businesses seeking to enhance operational efficiency, reduce costs, improve customer satisfaction, and gain a competitive edge. By considering the various components, functions, challenges, and strategies discussed in this article, businesses can design and manage a high-performing supply chain network that drives growth, profitability, and customer value in today’s dynamic business landscape.