Home>Finance>Taguchi Method Of Quality Control: Definition, Example, And Uses

Finance

Taguchi Method Of Quality Control: Definition, Example, And Uses

Published: February 5, 2024

Learn how the Taguchi Method of Quality Control is utilized for financial purposes through this comprehensive guide. Understand its definition, explore examples, and discover its various applications in the finance industry.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for LiveWell, at no extra cost. Learn more)

Welcome to the World of Taguchi Method of Quality Control!

If you’re looking for a powerful quality control technique that can help optimize product designs and improve manufacturing processes, then you’ve come to the right place. In this article, we’ll explore the Taguchi Method of Quality Control and its definition, give you an example of how it works, and discuss its countless uses in various industries.

Key Takeaways:

- The Taguchi Method of Quality Control is a statistical approach that aims to improve product quality and reduce variability in manufacturing processes.

- It was developed by Genichi Taguchi, a Japanese engineer, and has gained widespread adoption across industries globally.

What is the Taguchi Method of Quality Control?

The Taguchi Method of Quality Control, also known as Taguchi Design of Experiments (DOE), is a statistical approach to quality control that emphasizes proactive measures to reduce variability and improve product quality during the design and manufacturing stages. It focuses on understanding and minimizing the impact of various factors, known as noise factors, on product performance.

By optimizing product designs and manufacturing processes, the Taguchi Method aims to achieve robustness, which means that products are more resistant to variations in factors that are outside the control of the manufacturer or end-user. This approach helps to create products that consistently meet customer expectations, even when subjected to inevitable sources of variability.

Example of the Taguchi Method in Action

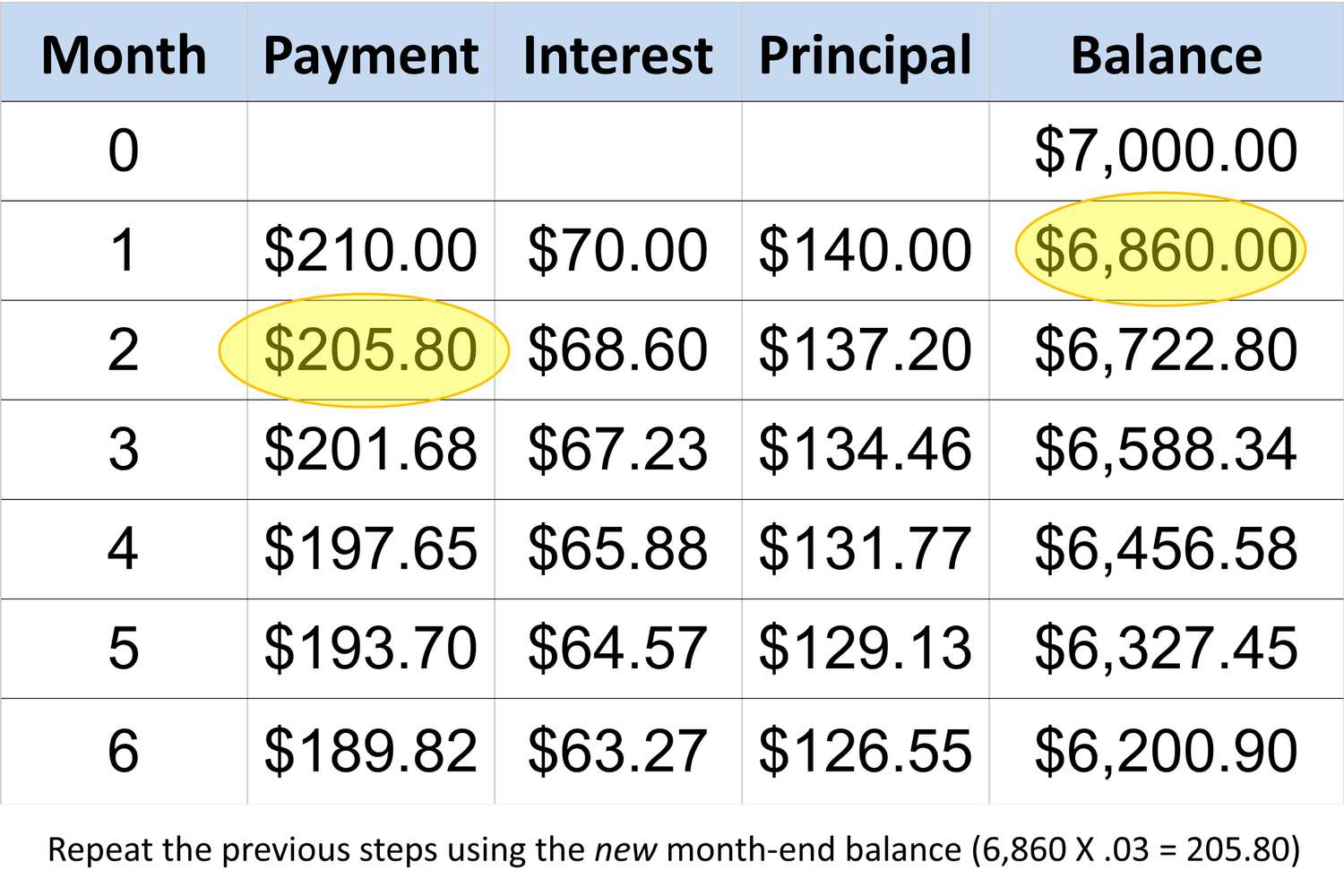

Let’s say a company manufactures car tires and wants to improve their durability. Using the Taguchi Method, they would identify all the potential noise factors that could affect tire durability, such as road conditions, temperature, and tire pressure. They would then design experiments to determine the optimal combination of factors that would result in the most durable tire.

With the Taguchi Method, the company would conduct a series of controlled experiments using a small number of test samples. By varying the noise factors systematically, they can determine which combination of factors leads to the best tire durability. This approach allows them to identify the optimal levels of each factor, even in the presence of unavoidable variability.

Uses of the Taguchi Method

The Taguchi Method of Quality Control is widely used in various industries for a wide range of applications. Here are some common uses:

- Product Design: The Taguchi Method helps optimize product performance by identifying the factors that have the most significant impact on quality and robustness. It can ensure that products meet customer expectations consistently.

- Process Improvement: Manufacturers can use the Taguchi Method to improve manufacturing processes, reduce variability, and minimize the likelihood of defects. This leads to increased efficiency and cost savings.

- Quality Assurance: The Taguchi Method enables companies to establish robust quality control plans that account for variability and external factors during the production process. This helps prevent defects and ensures consistent product quality.

- Research and Development: Researchers can use the Taguchi Method to optimize experimental designs and identify the critical factors that influence the outcome of their studies. This helps save time and resources.

- Service Industries: The Taguchi Method has also found applications in service industries, such as healthcare and hospitality, where it can optimize processes and improve customer satisfaction.

The Taguchi Method of Quality Control is a powerful tool that helps businesses improve product quality, manufacturing processes, and customer satisfaction. By proactively addressing variability and optimizing designs, companies can create robust products that consistently meet or exceed customer expectations. So, why not give this method a try and witness the positive impact it can have on your organization!