Home>Finance>How Does Work In Progress Affect Profit And Loss

Finance

How Does Work In Progress Affect Profit And Loss

Published: January 22, 2024

Learn how work in progress impacts your finance, profit, and loss. Understand the financial implications and optimize your business performance.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for LiveWell, at no extra cost. Learn more)

Table of Contents

Introduction

In the realm of finance and accounting, the concept of work in progress (WIP) holds significant weight in determining a company's financial standing. Understanding the implications of WIP on profit and loss is crucial for businesses aiming to maintain a healthy bottom line while effectively managing ongoing projects.

Work in progress refers to the inventory of unfinished goods in various stages of the production process. It represents the costs incurred for materials, labor, and overheads that have been invested in the production of goods that are yet to be completed. For companies engaged in manufacturing, construction, or any form of project-based work, WIP serves as a pivotal metric in assessing the utilization of resources and the efficiency of production processes.

The impact of work in progress on profit and loss is multifaceted, influencing key financial indicators and operational performance. Effectively managing WIP is essential for optimizing cash flow, accurately assessing project profitability, and maintaining healthy financial ratios. In this article, we delve into the intricacies of work in progress and explore its implications on the financial landscape. Furthermore, we'll elucidate strategies for managing WIP to mitigate adverse effects on profit and loss, ultimately fostering sustainable business growth and financial stability.

Understanding Work in Progress (WIP)

Work in progress, often abbreviated as WIP, encompasses the partially completed goods or services in the production process. It represents the cumulative costs incurred for materials, labor, and overheads associated with unfinished products or ongoing projects. WIP serves as a pivotal indicator of the capital tied up in the production cycle, reflecting the allocation of resources and the efficiency of production processes.

For manufacturing companies, WIP includes raw materials, labor expenses, and indirect costs such as utilities and depreciation, all of which contribute to the overall production value. In the construction industry, WIP encapsulates the costs of labor, materials, and overheads for ongoing projects, reflecting the investment in incomplete structures or developments. Service-based businesses also encounter WIP in the form of uncompleted projects or services in progress, where the associated costs are yet to be realized through revenue generation.

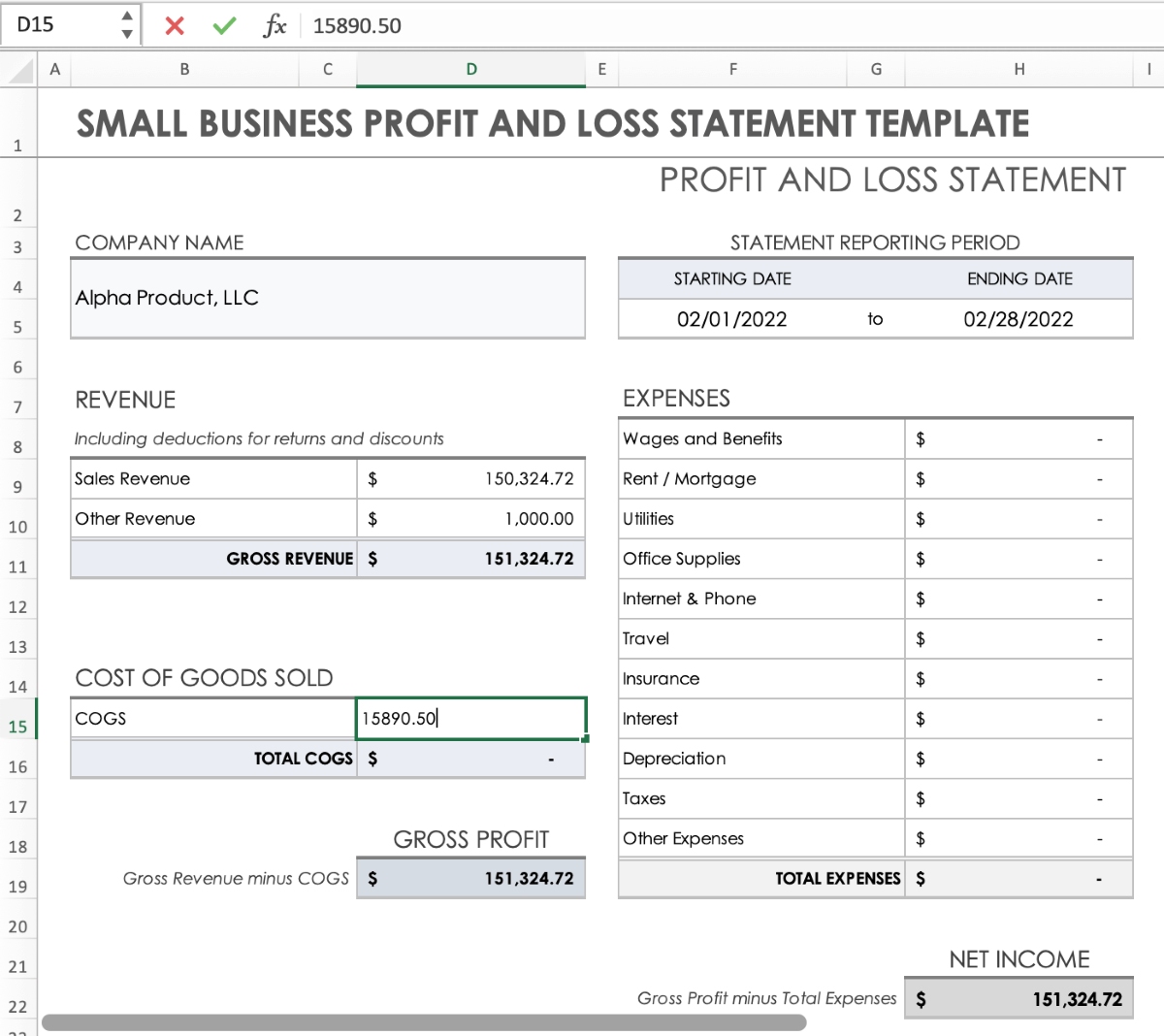

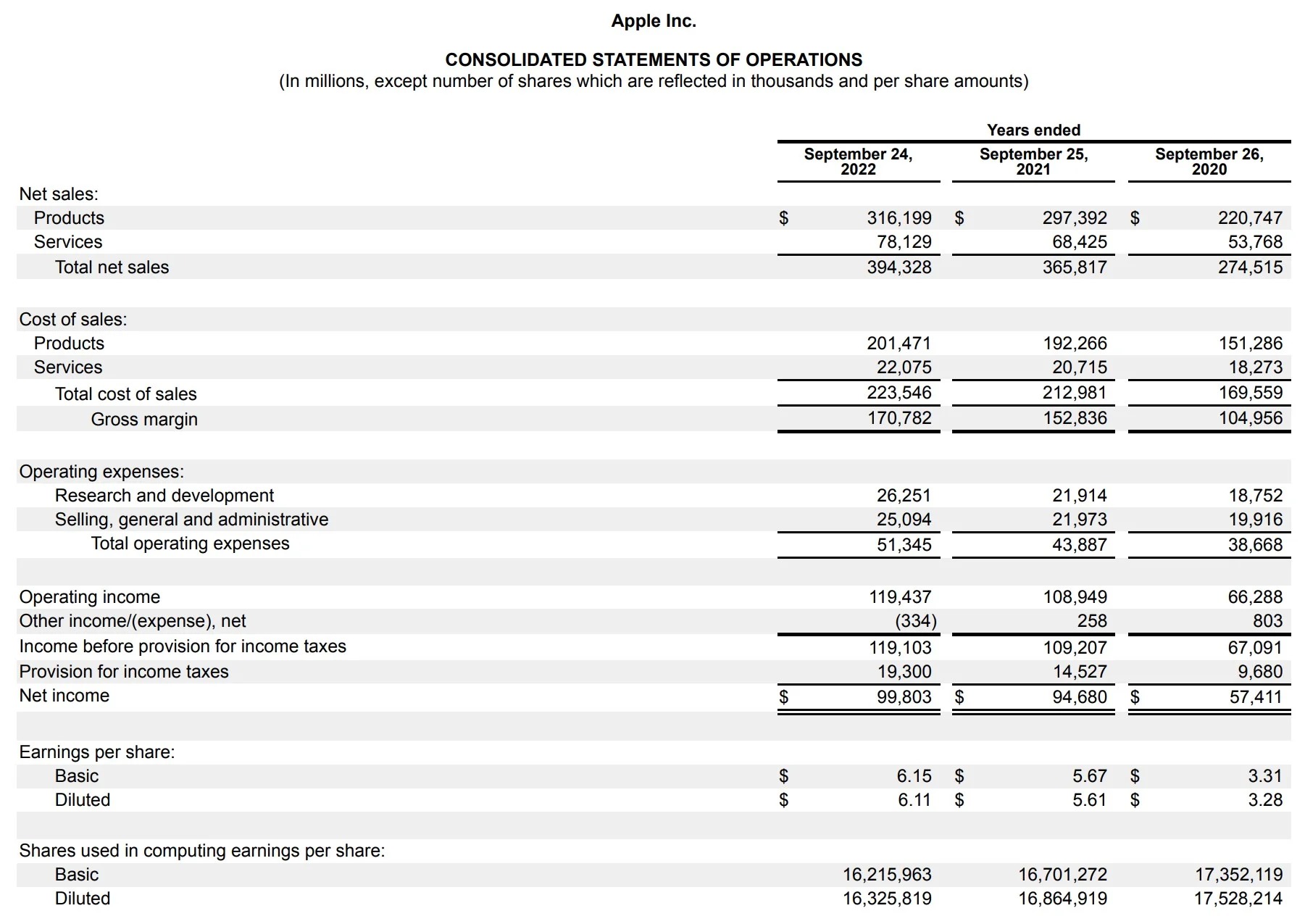

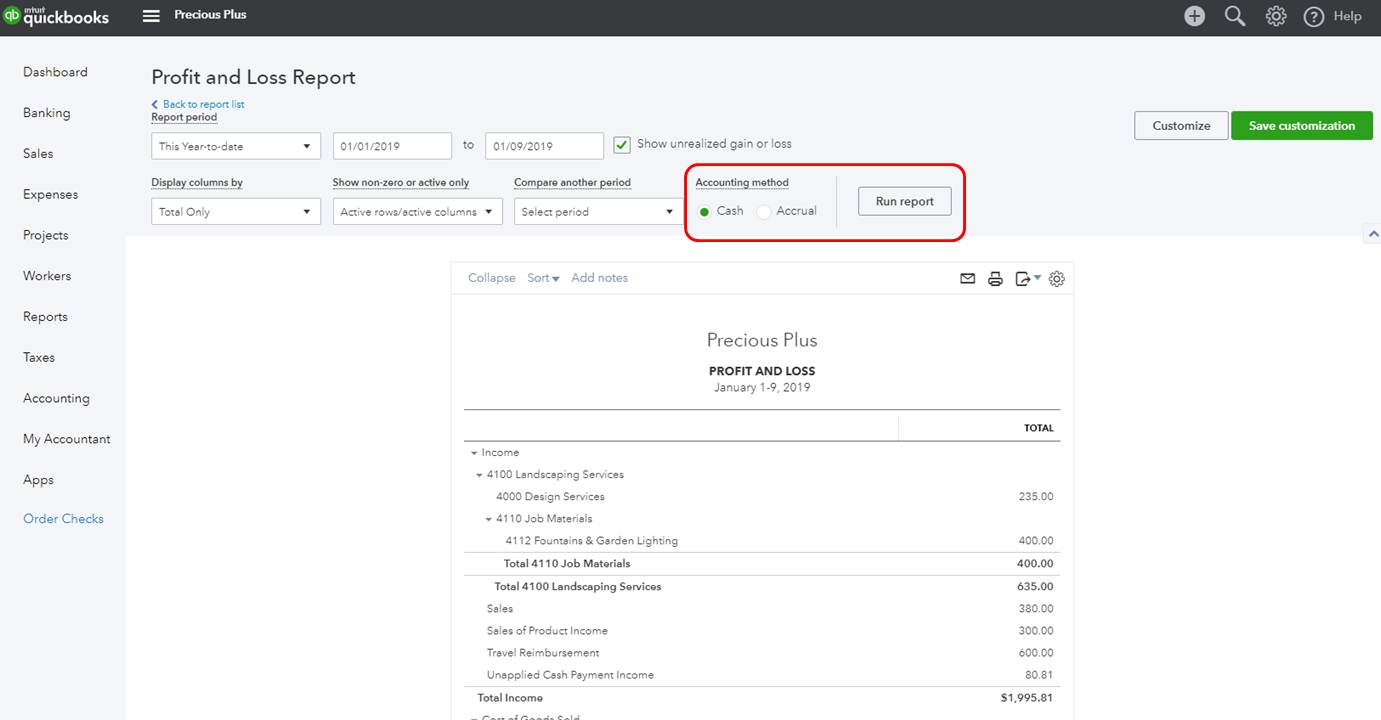

Understanding WIP is essential for businesses to accurately assess the true cost of production and determine the financial resources tied up in unfinished work. It provides insights into the utilization of resources, production bottlenecks, and the efficiency of project management. Additionally, WIP serves as a critical component in the calculation of the cost of goods sold (COGS) and the valuation of inventory, directly impacting the financial statements and profitability metrics.

Furthermore, WIP plays a pivotal role in project accounting, enabling businesses to track the costs incurred for specific projects and allocate expenses accurately. This facilitates the monitoring of project profitability and the identification of potential cost overruns or inefficiencies in resource utilization. Effectively managing WIP involves maintaining a balance between optimizing production processes, minimizing idle inventory, and ensuring the timely completion of projects to realize revenue.

Impact of Work in Progress on Profit and Loss

The presence of work in progress (WIP) significantly influences a company’s profit and loss statements, exerting both direct and indirect effects on financial performance. Understanding the impact of WIP on profit and loss is paramount for businesses seeking to accurately evaluate their operational efficiency and overall profitability.

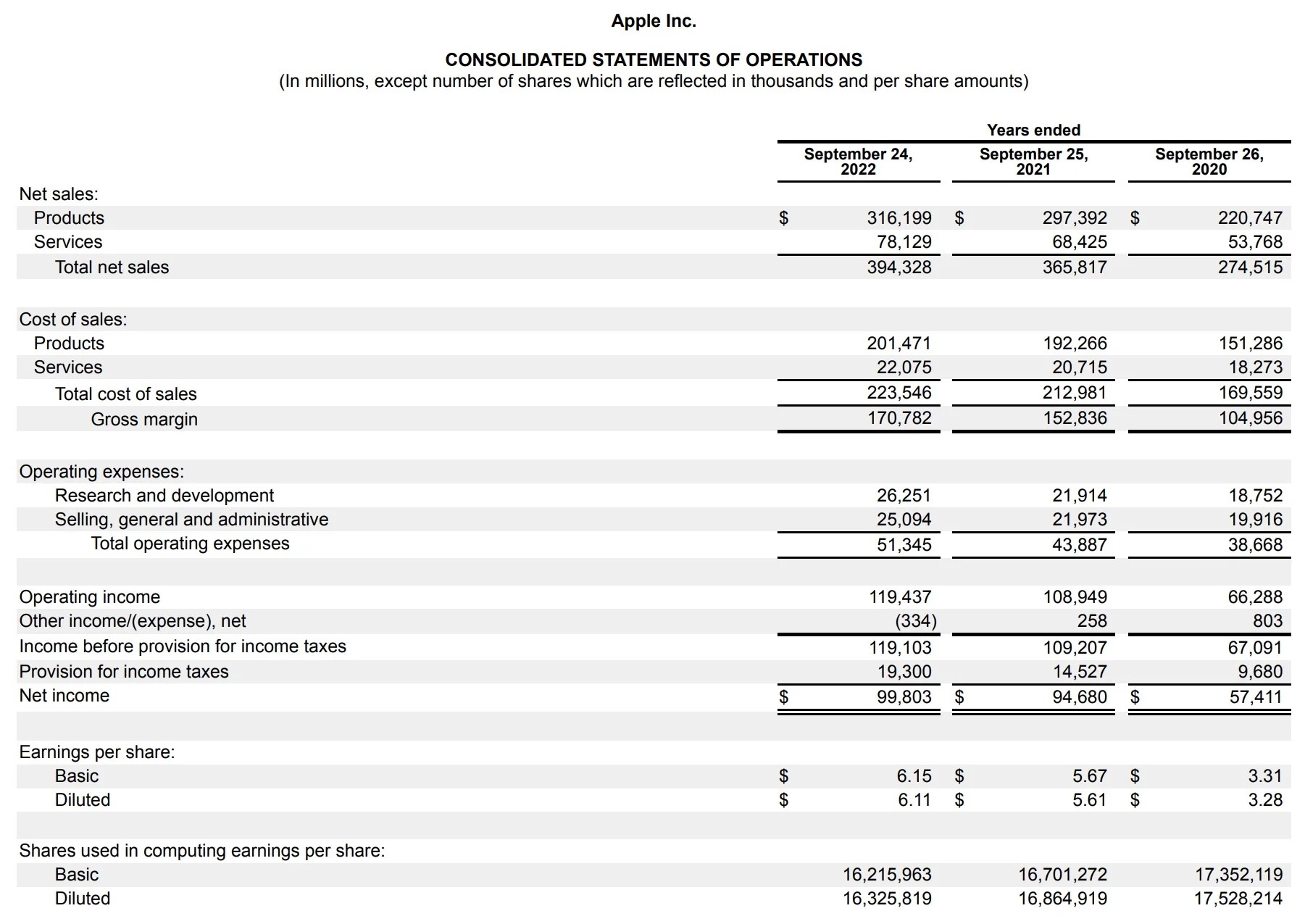

One of the primary ways in which WIP affects profit and loss is through the allocation of costs. WIP represents the accumulation of direct material, direct labor, and manufacturing overhead costs associated with unfinished products or ongoing projects. As a result, these costs are not immediately recognized as expenses in the income statement until the completion of the production process. This deferral of costs directly impacts the recognition of revenue, subsequently influencing the profitability of the business.

Moreover, the presence of significant WIP levels can indicate inefficiencies in production processes, leading to longer lead times, increased carrying costs, and potential bottlenecks in the workflow. These inefficiencies can result in higher production costs, reduced profit margins, and a negative impact on the overall financial performance of the company.

Additionally, the valuation of inventory, including work in progress, directly influences the cost of goods sold (COGS) and the determination of gross profit. Fluctuations in WIP levels can impact the accuracy of inventory valuation, potentially leading to distorted financial metrics and misrepresentation of the company’s financial health.

Furthermore, the management of WIP directly impacts cash flow and working capital management. Excessive WIP levels can tie up financial resources, leading to reduced liquidity and potential constraints on funding other operational requirements. On the other hand, inadequate WIP levels can result in production delays, impacting revenue recognition and cash inflows.

Effectively managing WIP is essential for optimizing profit and loss statements, ensuring accurate cost allocation, and maintaining healthy financial ratios. By streamlining production processes, minimizing idle inventory, and enhancing project management, businesses can mitigate the adverse effects of WIP on profitability, fostering sustainable financial growth and operational efficiency.

Strategies to Manage Work in Progress

Effective management of work in progress (WIP) is critical for businesses to optimize operational efficiency, maintain healthy cash flow, and enhance overall profitability. Implementing strategic approaches to manage WIP can mitigate the adverse effects on financial performance and ensure the timely completion of projects while minimizing idle inventory.

1. Streamlining Production Processes: Enhancing production workflows and minimizing process inefficiencies can significantly reduce WIP levels. Implementing lean manufacturing principles, optimizing production schedules, and reducing lead times can streamline operations, leading to lower WIP accumulation and improved resource utilization.

2. Project Management and Monitoring: Utilizing robust project management methodologies and tools allows businesses to track the progress of ongoing projects, allocate resources effectively, and identify potential bottlenecks in the production cycle. Real-time monitoring of project timelines and costs enables proactive decision-making to minimize WIP accumulation and optimize project profitability.

3. Demand Forecasting and Inventory Management: Accurate demand forecasting and inventory management play a pivotal role in managing WIP. By aligning production levels with anticipated demand, businesses can prevent overproduction, minimize excess inventory, and reduce WIP levels, leading to improved cash flow and reduced carrying costs.

4. Collaboration with Suppliers and Vendors: Establishing collaborative relationships with suppliers and vendors can facilitate the timely delivery of materials and components, reducing lead times and minimizing WIP accumulation. Just-in-time (JIT) inventory practices and vendor-managed inventory (VMI) arrangements can optimize supply chain efficiency, contributing to lower WIP levels.

5. Continuous Process Improvement: Embracing a culture of continuous improvement and operational excellence enables businesses to identify and address inefficiencies in production processes. Implementing Kaizen principles, conducting regular process audits, and empowering employees to contribute to process optimization can lead to reduced WIP levels and enhanced operational performance.

6. Cost Management and Analysis: Conducting thorough cost analysis and cost management initiatives allows businesses to identify areas of excessive spending and resource utilization. By optimizing cost structures, businesses can minimize WIP accumulation and enhance profitability while maintaining a competitive edge in the market.

By implementing these strategic approaches, businesses can effectively manage work in progress, optimize production processes, and mitigate the adverse effects of WIP on profit and loss. Proactive management of WIP not only fosters financial stability but also enhances overall operational efficiency, positioning businesses for sustained growth and competitiveness in their respective industries.

Conclusion

Work in progress (WIP) plays a pivotal role in shaping the financial landscape of businesses engaged in manufacturing, construction, and project-based endeavors. The impact of WIP on profit and loss is multifaceted, influencing cost allocation, revenue recognition, and overall operational efficiency. Understanding the implications of WIP on financial performance is essential for businesses to navigate the complexities of production management and maintain a healthy bottom line.

Effectively managing WIP requires a strategic approach encompassing streamlined production processes, robust project management, demand forecasting, collaborative supply chain practices, continuous process improvement, and diligent cost management. By implementing these strategies, businesses can optimize resource utilization, minimize idle inventory, and enhance project profitability, ultimately fostering sustainable financial growth and operational excellence.

Striking a balance between efficient production management and WIP optimization is paramount for businesses to maintain healthy cash flow, accurately assess project profitability, and drive overall financial stability. Through proactive WIP management, businesses can mitigate the adverse effects on profit and loss, ensuring accurate cost allocation, and maintaining healthy financial ratios.

In conclusion, work in progress is not merely a metric of unfinished goods or ongoing projects; it is a critical component that shapes the financial health and operational efficiency of businesses. By embracing strategic WIP management practices, businesses can navigate the complexities of production management, optimize profitability, and position themselves for sustained growth and success in an increasingly competitive business landscape.