Finance

Where Does The Supply Chain End?

Published: October 20, 2023

Discover how finance plays a pivotal role in the supply chain, from managing costs to ensuring seamless transactions. Explore where the supply chain ends and the financial impacts that follow.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for LiveWell, at no extra cost. Learn more)

Table of Contents

- Introduction

- Defining the Supply Chain

- The Traditional Supply Chain Model

- Expanding the Boundaries of the Supply Chain

- Supply Chain Integration

- The Role of Technology in Extending the Supply Chain

- Challenges in Determining the End of the Supply Chain

- Environmental Considerations in the Supply Chain

- Ethical Concerns in the Extended Supply Chain

- Conclusion

Introduction

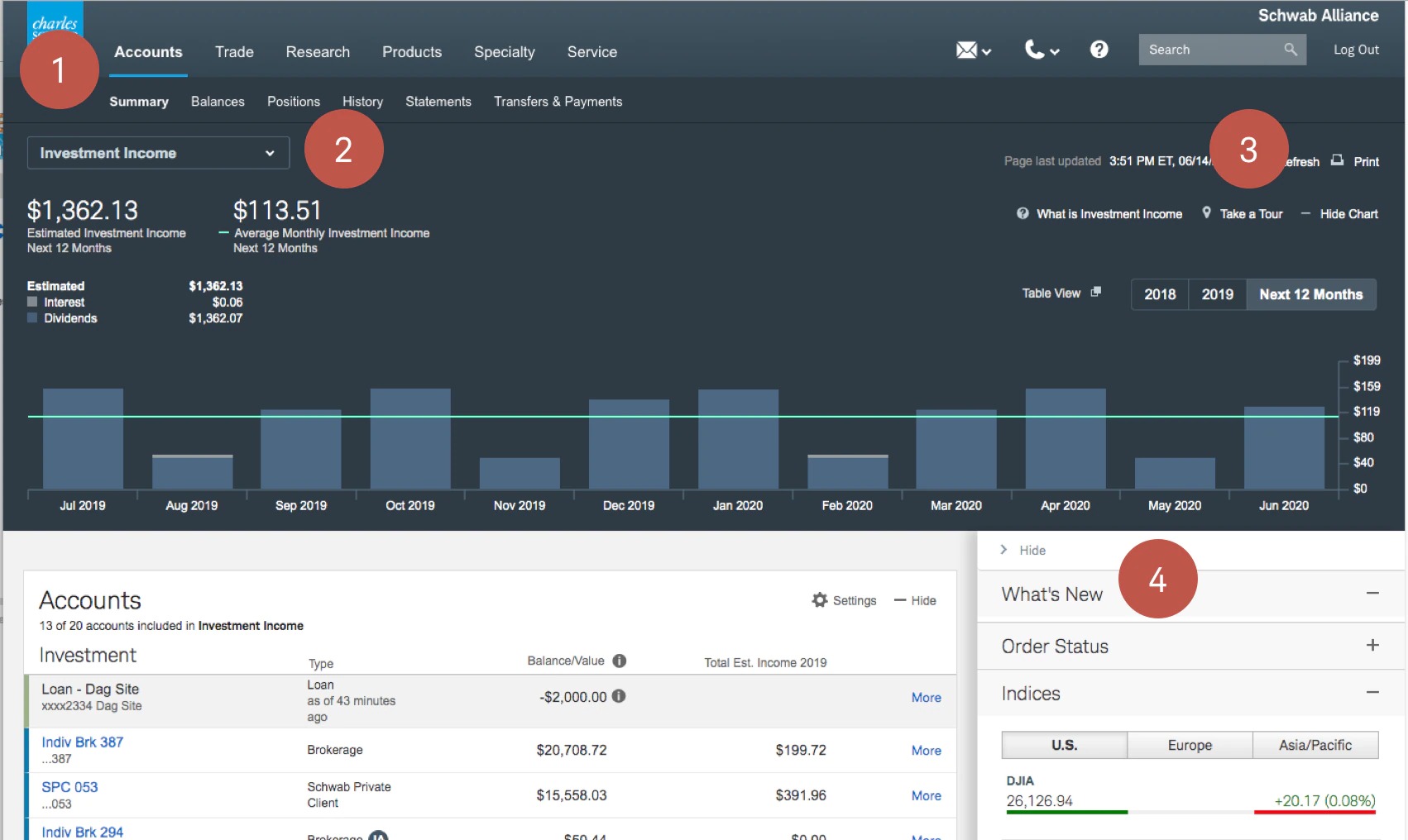

The supply chain is a critical component of any business, encompassing the entire journey of a product or service from its creation to its delivery to the end customer. Traditionally, the supply chain has been viewed as a linear process, with a clear starting point and an end point. However, as business practices and technologies evolve, the boundaries of the supply chain are becoming more fluid and extend beyond the traditional model.

In this article, we will explore the concept of the supply chain and its evolving nature. We will delve into how the traditional supply chain model is expanding to encompass a wider range of activities and stakeholders. We will also discuss the role of technology in extending the supply chain and the challenges that arise when determining its end. Finally, we will touch upon the environmental and ethical considerations that come into play in the extended supply chain.

By understanding the complexities and nuances of the supply chain, businesses can optimize their operations, ensure efficient delivery of products or services, and make informed decisions that align with their sustainability and ethical goals.

Defining the Supply Chain

The supply chain can be broadly defined as the network of organizations, resources, activities, and technologies involved in the creation, production, distribution, and delivery of a product or service to the end customer. It involves the coordination and integration of multiple entities, including suppliers, manufacturers, logistics providers, retailers, and customers.

At its core, the supply chain is responsible for transforming raw materials into finished products and ensuring their availability to meet customer demand. It encompasses various stages, such as procurement of raw materials, production, inventory management, transportation, and customer service.

Supply chains can be complex and dynamic, varying in structure and scope depending on the industry, product type, and geographical reach. For example, a supply chain in the manufacturing industry may involve sourcing raw materials globally, manufacturing in multiple locations, and distributing products worldwide. On the other hand, a supply chain in the retail industry may focus on optimizing inventory management, logistics, and customer fulfillment.

Effective supply chain management is crucial for businesses to operate efficiently and meet customer expectations. It involves strategic planning, coordination, and collaboration among the various stakeholders to ensure the smooth flow of goods, information, and funds across the supply chain network.

Supply chain management encompasses activities such as demand forecasting, procurement, production planning, inventory management, transportation, warehousing, and customer service. It aims to minimize costs, optimize resource allocation, improve efficiency, and enhance customer satisfaction.

Over the years, the concept of supply chain management has evolved, moving beyond the traditional focus on cost reduction and operational efficiency to include considerations of sustainability, risk management, and ethical practices.

The Traditional Supply Chain Model

In the traditional supply chain model, the journey of a product starts with the acquisition of raw materials and ends with the delivery of the finished product to the end customer. It follows a linear flow, with each stage of the process occurring sequentially.

The traditional model typically involves the following stages:

- Procurement: This stage involves sourcing and acquiring the necessary raw materials or components from suppliers.

- Production: Once the materials are procured, they are transformed into finished goods through various manufacturing processes.

- Warehousing and Distribution: The finished products are stored in warehouses and then distributed to retailers or customers through a predetermined logistics network.

- Retail: In this stage, the products are made available for purchase by the end customers through physical stores or online platforms.

- Customer: Finally, the product is purchased and used by the end customer, completing the supply chain journey.

This linear model involves a clear demarcation between the different stages, with handoffs occurring between each step. Each participant in the supply chain plays a specific role and is responsible for a specific set of tasks and activities.

The traditional supply chain model operates on the assumption that resources are utilized efficiently, costs are minimized, and customer demand is accurately forecasted. However, this model has its limitations, especially in today’s dynamic and globalized business landscape.

One key limitation is the lack of visibility and coordination across the supply chain. With each stage operating independently, information flow and communication can be fragmented, leading to delays, inefficiencies, and the inability to respond effectively to changes in demand or disruptions in the supply chain.

Additionally, the traditional model may not fully account for sustainability and ethical considerations. It often focuses primarily on cost reduction, overlooking the environmental and social impacts of the supply chain activities.

As a result, businesses are increasingly recognizing the need to move beyond the traditional supply chain model and embrace a more integrated and sustainable approach to supply chain management.

Expanding the Boundaries of the Supply Chain

In recent years, there has been a shift in mindset regarding the boundaries of the supply chain. Businesses are recognizing that the traditional linear model is no longer sufficient to meet the demands of today’s dynamic and interconnected world. The boundaries of the supply chain are expanding to include various activities and stakeholders beyond the traditional model.

One key aspect of this expansion is the inclusion of suppliers and vendors as integral parts of the supply chain network. Rather than treating suppliers as external entities, businesses are now recognizing the importance of building strong partnerships and collaboration with suppliers. This entails sharing information, fostering innovation, and jointly working towards improving sustainability and ethical practices throughout the supply chain.

Furthermore, the concept of supply chain integration is becoming increasingly prevalent. Organizations are realizing the benefits of seamlessly connecting their internal processes with external partners, such as suppliers, manufacturers, distributors, and logistics providers. Supply chain integration allows for real-time information sharing, improved coordination, and enhanced visibility across the entire value chain. This integration can drive efficiency, reduce costs, and facilitate faster response times to customer needs.

Another significant expansion of the supply chain boundaries is the inclusion of reverse logistics. Traditionally, the focus has been on the forward flow of goods, from suppliers to customers. However, reverse logistics encompasses the process of handling product returns, repairs, recycling, and disposal. By effectively managing reverse logistics, businesses can recover value from returned products, reduce waste, and minimize environmental impact.

Moreover, the concept of the extended supply chain recognizes the impact of activities beyond the direct control of a business. This includes the consideration of upstream and downstream activities, such as the sourcing of raw materials, transportation, and end-of-life product disposal. By examining the entire lifecycle of a product and taking responsibility for its environmental and social impact, businesses can ensure a more sustainable and ethical supply chain.

Overall, expanding the boundaries of the supply chain is crucial for businesses to adapt to a rapidly changing business landscape. By embracing supplier collaboration, supply chain integration, reverse logistics, and considering the extended supply chain, organizations can improve efficiency, sustainability, and customer satisfaction.

Supply Chain Integration

Supply chain integration is the process of connecting and aligning various entities within a supply chain network to achieve improved coordination, streamlined processes, and enhanced visibility. It involves the seamless flow of information, materials, and resources across the entire supply chain, from suppliers to end customers.

Supply chain integration enables organizations to collaborate closely with suppliers, manufacturers, distributors, retailers, and other stakeholders. Integrated supply chains facilitate real-time sharing of data, which allows for informed decision-making and faster responses to changes in demand or supply.

There are several key benefits associated with supply chain integration:

- Improved Efficiency: By integrating processes and systems across the supply chain, organizations can eliminate redundancies, reduce delays, and improve overall operational efficiency. This leads to cost savings, increased productivity, and faster time-to-market.

- Enhanced Visibility: Supply chain integration provides greater visibility into inventory levels, production schedules, and transportation status. This enables businesses to have a holistic view of the supply chain, identify bottlenecks, and proactively address any issues that may arise.

- Better Demand Planning: With integrated supply chains, businesses can access accurate and real-time demand information. This facilitates more effective demand planning, reducing the risk of stockouts or overstocking and ensuring optimal inventory levels.

- Responsive to Customer Needs: Supply chain integration allows organizations to be more responsive to customer demands and preferences. By having a clear understanding of customer requirements and real-time information across the supply chain, businesses can tailor their products or services accordingly.

- Collaboration and Innovation: Integrated supply chains foster closer collaboration and innovation with suppliers and other stakeholders. By sharing information, insights, and ideas, organizations can collectively work towards improvements in product quality, cost reductions, and sustainability initiatives.

- Risk Mitigation: With integrated supply chains, businesses are better equipped to identify and manage risks throughout the supply chain. This includes anticipating potential disruptions, implementing contingency plans, and diversifying sourcing and logistics options.

While supply chain integration offers numerous benefits, it also presents challenges. These challenges include technological compatibility, data security, cultural differences among supply chain partners, and the need for effective change management. However, with careful planning, clear communication, and the right tools and technologies, these challenges can be overcome, resulting in a more efficient and resilient supply chain.

Overall, supply chain integration is crucial for organizations to stay competitive in today’s fast-paced and interconnected business environment. By fostering collaboration, enhancing visibility, and optimizing processes, businesses can achieve greater efficiency, improved customer satisfaction, and sustainable growth.

The Role of Technology in Extending the Supply Chain

Technology plays a crucial role in extending the boundaries of the supply chain and enabling businesses to embrace a more interconnected and integrated approach. Advancements in digital technologies have revolutionized how supply chains operate, enabling greater visibility, efficiency, and collaboration across the entire value chain.

Here are some ways technology is extending and transforming the supply chain:

- Data and Analytics: With the proliferation of data capture and analytics capabilities, businesses can collect and analyze vast amounts of information across the supply chain. This data provides valuable insights into customer behavior, demand patterns, inventory levels, and production processes. By leveraging these insights, organizations can make more accurate forecasts, optimize inventory levels, improve production planning, and enhance overall supply chain visibility.

- Internet of Things (IoT): IoT devices, such as sensors and RFID tags, enable the tracking and monitoring of goods, assets, and processes in real-time. This provides businesses with real-time visibility and control over their supply chain operations. IoT also facilitates automated data capture, reducing manual entry errors and improving efficiency in tasks like inventory management, quality control, and asset tracking.

- Blockchain: Blockchain technology provides secure, decentralized, and immutable transaction records. In the supply chain context, blockchain enables transparency and traceability of products from source to end customer. It helps organizations track and verify the authenticity of products, ensure ethical sourcing, and reduce the risk of counterfeit goods. Blockchain also facilitates streamlined payment processes and eliminates intermediaries, reducing costs and enhancing trust among supply chain partners.

- Artificial Intelligence (AI) and Machine Learning: AI and machine learning algorithms can analyze vast amounts of supply chain data and provide valuable insights and recommendations. These technologies can identify patterns, optimize routing and scheduling, predict demand fluctuations, and automate decision-making processes. AI-powered chatbots and virtual assistants also enhance customer service by providing instant responses and personalized assistance.

- Cloud Computing: Cloud-based platforms provide a centralized repository for supply chain data, enabling seamless collaboration and information sharing across multiple stakeholders. This fosters greater visibility, transparency, and real-time communication within the supply chain network. Cloud solutions also offer scalability and flexibility, allowing businesses to adapt to changing market demands and easily integrate with external partners.

- Robotic Process Automation (RPA): RPA automates repetitive and rule-based tasks within the supply chain, such as data entry, order processing, and invoicing. By freeing up human resources from mundane tasks, RPA improves efficiency, reduces errors, and enables employees to focus on value-added activities.

By leveraging these technologies, businesses can extend their supply chains beyond traditional boundaries and achieve greater agility, efficiency, and responsiveness. These advancements enable seamless collaboration, end-to-end visibility, and the ability to quickly adapt to changing market demands. Ultimately, technology empowers organizations to optimize their operations, provide enhanced customer experiences, and drive sustainable growth in the extended supply chain.

Challenges in Determining the End of the Supply Chain

Determining the end of the supply chain can be challenging, particularly as the boundaries of the supply chain continue to expand and evolve. In the traditional model, the end of the supply chain is typically seen as the point of product delivery to the end customer. However, in today’s complex business landscape, several factors contribute to the ambiguity surrounding the end of the supply chain.

Here are some key challenges in determining the end of the supply chain:

- Extended Value Chain: As supply chains become more interconnected and integrated, businesses are recognizing that the supply chain does not end with product delivery. The concept of the extended value chain considers the entire lifecycle of a product, including post-purchase services, customer support, and end-of-life product management. This extended value chain challenges traditional notions of where the supply chain ends, as customer interactions and support continue long after the initial purchase.

- Omni-Channel Distribution: With the rise of e-commerce and omni-channel retailing, businesses are now managing multiple distribution channels simultaneously. Customers can purchase products online, in physical stores, or through third-party marketplaces. The complexity of managing these channels blurs the lines of where the supply chain ends, as the final delivery point may vary depending on the customer’s chosen sales channel.

- International Supply Chains: The global nature of supply chains adds complexity to determining the end point. International trade involves multiple customs checkpoints, transportation modes, and regulatory requirements. The final destination of a product may not necessarily be the end customer but a distribution center or a customs hub. This creates challenges in demarcating where the supply chain ends and where local distribution or fulfillment starts.

- Service-Based Offerings: In industries that primarily offer services rather than tangible products, determining the end of the supply chain becomes even more complex. For example, in the financial or consulting sector, the delivery of a service may involve multiple interactions and touchpoints over an extended period. Identifying the precise endpoint in such cases can be subjective and dependent on the specific service agreement.

- Outsourcing and Subcontracting: Many businesses outsource certain activities or work with subcontractors to fulfill customer orders. These outsourcing relationships often involve interdependencies and handoffs that extend beyond the boundaries of the organization. Defining the end of the supply chain in these scenarios can be challenging, as the responsibility for delivering the final product or service may rest with a third-party entity.

Addressing these challenges requires a broader perspective and a shift in mindset. Instead of focusing solely on the physical delivery of products, businesses should consider the entire customer experience, the lifecycle of their offerings, and the network of relationships and activities involved. By taking a holistic approach, organizations can better manage their supply chains and adapt to the ever-evolving nature of the business environment.

Environmental Considerations in the Supply Chain

In recent years, there has been a growing emphasis on the environmental impacts of supply chain operations. Businesses are recognizing the need to incorporate environmental considerations into their supply chain strategies to reduce resource consumption, minimize waste generation, and mitigate the ecological footprint of their operations.

Here are some key environmental considerations in the supply chain:

- Sustainable Sourcing: One important aspect of environmental considerations in the supply chain is the sourcing of raw materials. Organizations are seeking sustainable and eco-friendly sources of raw materials to reduce negative environmental impacts. This includes sourcing from suppliers who adhere to responsible forestry practices, engage in fair trade, and promote biodiversity conservation.

- Reducing Carbon Footprint: Supply chain operations often contribute significantly to greenhouse gas emissions, mainly through transportation and logistics activities. Businesses are adopting strategies to reduce their carbon footprint by optimizing transportation routes, embracing alternative fuels, and exploring greener transportation options such as electric vehicles or rail transport. This helps minimize the environmental impacts of their supply chain activities.

- Energy Efficiency: Another critical aspect of environmental considerations in the supply chain is energy efficiency. Businesses are implementing energy-saving measures in their manufacturing processes, warehouses, and distribution centers. This includes investing in energy-efficient technologies, optimizing equipment usage, and adopting renewable energy sources to power their operations.

- Waste Reduction and Recycling: Minimizing waste generation and promoting recycling throughout the supply chain is crucial for environmental sustainability. Businesses are implementing waste management strategies, such as implementing waste reduction programs, segregating waste streams, and partnering with recycling vendors. This helps divert waste from landfills and promotes the circular economy.

- Lifecycle Assessments: Conducting lifecycle assessments of products is essential in understanding their environmental impact. Organizations are evaluating their products’ entire lifecycle, from raw material extraction to disposal, to identify potential environmental hotspots and implement measures to reduce their impact. This includes designing products for recyclability or considering end-of-life options such as take-back programs or remanufacturing.

- Supplier Collaboration: Collaboration with suppliers is critical in addressing environmental considerations in the supply chain. Organizations are engaging with suppliers to promote sustainable practices and encourage them to implement environmental management initiatives. This includes supplier audits, environmental certifications, and capacity-building programs to enhance sustainability across the entire supply chain.

By integrating environmental considerations into the supply chain, businesses can achieve both environmental sustainability and business success. Sustainable supply chain practices not only help protect the environment but also improve operational efficiency, reduce costs, enhance brand reputation, and meet the increasing demand for eco-friendly products and services.

Ethical Concerns in the Extended Supply Chain

As the boundaries of the supply chain extend, ethical concerns become increasingly relevant and important. Organizations are expected to uphold high ethical standards not only within their own operations but also throughout the entire extended supply chain. Ethical concerns encompass a range of issues, including labor rights, human rights, fair trade, responsible sourcing, and social and community impacts.

Here are some key ethical considerations in the extended supply chain:

- Labor Rights: Ensuring fair and safe working conditions for employees within the supply chain is critical. Businesses are expected to adopt and enforce labor standards that prevent practices such as forced labor, child labor, and workplace discrimination. This includes auditing and monitoring suppliers and promoting transparency and accountability in labor practices.

- Human Rights: Respecting and upholding human rights is a fundamental ethical obligation. Organizations must be vigilant in their supply chains to prevent any violation of human rights, including the right to freedom, dignity, and equality. This involves conducting due diligence to identify and address potential human rights risks and engaging with suppliers to promote ethical practices.

- Fair Trade: Fair trade is a concept that promotes equitable and sustainable trading practices. Businesses are encouraged to support fair trade principles by providing fair prices to suppliers, promoting safe and healthy working conditions, and ensuring transparency and traceability in supply chain operations. Fair trade certification programs provide assurance to consumers that products are sourced ethically.

- Responsible Sourcing: Organizations have a responsibility to ensure that the raw materials and components used in their products are sourced responsibly. This includes avoiding materials linked to environmental degradation, human rights abuses, or conflict zones. Responsible sourcing involves conducting supply chain due diligence, engaging with suppliers, and promoting sustainable and ethical sourcing practices.

- Community Impacts: Extended supply chains can have significant social and community impacts. Businesses should consider the welfare and well-being of the communities in which they operate, including respecting indigenous rights, supporting local economies, and minimizing negative social impacts. This entails engaging with local stakeholders, conducting social impact assessments, and implementing community development initiatives.

- Transparency and Disclosure: Transparency is crucial in addressing ethical concerns in the supply chain. Organizations are expected to provide clear and accurate information about their supply chain practices, including supplier relationships, sourcing policies, and efforts to address ethical concerns. This enables stakeholders, including customers, investors, and advocacy groups, to make informed decisions and hold businesses accountable.

Addressing ethical concerns in the extended supply chain requires proactive measures and ongoing commitment. It involves collaboration with suppliers, adherence to internationally recognized standards, and continuous improvement in ethical practices. By prioritizing ethics throughout the supply chain, organizations can not only build trust and loyalty with stakeholders but also contribute to positive social and environmental outcomes.

Conclusion

The supply chain is no longer a simple linear process with a clear starting point and endpoint. It has evolved into a complex network of activities and stakeholders that extend beyond traditional boundaries. In this article, we explored the various aspects of the evolving supply chain landscape.

We began by defining the supply chain and understanding its traditional model. However, as businesses adapt to new demands and technologies, the boundaries of the supply chain are expanding. We discussed how the supply chain now includes extended value chain considerations, supply chain integration, reverse logistics, and the impact of outsourcing and subcontracting.

Technology plays a crucial role in extending the supply chain and enabling businesses to achieve seamless coordination, improved efficiency, and enhanced visibility. We explored the role of technology in areas such as data analytics, Internet of Things (IoT), blockchain, artificial intelligence (AI), cloud computing, and robotic process automation (RPA).

Additionally, we highlighted the challenges in determining the end of the supply chain and discussed the importance of environmental considerations and ethical practices. Sustainable sourcing, reducing the carbon footprint, energy efficiency, waste reduction, and responsible supplier collaborations are critical in building an environmentally conscious supply chain. Ethical concerns, such as labor rights, human rights, fair trade, responsible sourcing, and community impacts, should also be considered.

In conclusion, the supply chain is a dynamic and interconnected ecosystem that requires a holistic approach. Businesses must embrace the expanding boundaries of the supply chain, leverage technology, and prioritize environmental and ethical considerations. By doing so, organizations can optimize their operations, reduce risks, meet customer expectations, and contribute to a sustainable and responsible global supply chain.